Chiyambi: M'zaka zaposachedwapa, chifukwa cha kukwera mofulumira kwa magalimoto atsopano amphamvu ndi luntha lochita kupanga, kufunikira kwa ma semiconductors kwapitirira kukula. Kukula mwachangu kwa ukadaulo wanzeru kwathandizira kusintha kwa kukula kwa ma semiconductor kuchokera pamlingo wa microelectronic kupita pamlingo wa atomiki. Ma semiconductors a m'badwo wachitatu ayambitsa nthawi yatsopano ya chitukuko chapamwamba! Nthawi yomweyo, njira yopangira nayonso ndi yovuta kwambiri. Ndi zinthu ziti zochokera ku Hikelok zomwe zingathandize pakukula kwa ma semiconductor? Tiyeni tiphunzire zambiri pamodzi!

Ukadaulo watsopano monga nzeru zopanga zinthu ndi deta yayikulu ndi zinthu zofunika kwambiri pakukula kwa zinthu, zomwe zimapangitsa kuti pakhale kufunika kokonza magwiridwe antchito ambiri m'ma chips ang'onoang'ono. Izi zikutanthauza kuti njira yopangira zinthu idzakhala yovuta kwambiri, ikufunika mphamvu zoyankhira mwachangu komanso kudalirika kwambiri kuti zinthu ziyende bwino kwambiri kuti zitsimikizire kuti kunyamula mankhwala molondola kwambiri kudzakhala patsogolo.

Chifukwa cha kulondola komanso kusinthasintha kwa kupanga ma chip a semiconductor, kaya ndi ma valve owongolera mpweya molondola kapena zolumikizira mapaipi zonyamulira mpweya wamagetsi, ayenera kutsatira miyezo yoyenera ya ASTM ndi SEMI ndikukhala ndi makhalidwe awa:

1. Zipangizo zopangira zitsulo zosapanga dzimbiri ziyenera kuyengedwa pogwiritsa ntchito VAR kapena VIM-VAR yoyera kwambiri kuti zitsimikizire kuti kuyera kwambiri kuchokera ku gwero kukufunika;

2. Pamwamba pa chinthucho pakakhudzana ndi chinthucho pamafunika kuchita zinthu monga kupukuta ndi kupukuta pogwiritsa ntchito magetsi kuti chikhale choyera kwambiri pamene chikulimbitsa kukana kwa dzimbiri kwa chinthucho;

3. Zinthu zopangidwa ndi zitsulo zosapanga dzimbiri ndi pulasitiki ziyenera kukwaniritsa miyezo yoyenera ya ASTM ndi SEMI monga kuwongolera kusanthula kwa chinyezi chamkati, kuwongolera kusanthula kwa kaboni yonse yachilengedwe (TOC), ndi kuwongolera kapangidwe ka kuipitsidwa kwa ayoni.

Zogulitsa za Hikelok zoyera kwambirikukwaniritsa zofunikira za makampani opanga ma semiconductor pazinthu zamadzimadzi ndikutsatira miyezo ya ASTM ndi SEMI, kuphatikiza kusankha zinthu zopangira, ukadaulo wapamwamba kwambiri wopangira zinthu, ndi kuyesa kopanga mu workshop yopanda fumbi la 100 level. Mitundu ya zinthuzo ndi monga ma valve ochepetsa kupanikizika koyera kwambiri, ma valve a diaphragm oyera kwambiri, ma valve otsekedwa oyera kwambiri, mapanelo ophatikizidwa, zolumikizira zoyera kwambiri, ndi machubu a EP. Pali mitundu yosiyanasiyana ya kukula komwe kulipo, ndipo kusintha kumatha kupangidwa malinga ndi zofunikira pakuyika pamalopo.

1,Zovala zoyera kwambiri & Zolumikizira zolumikizidwa ndi matako

Kugwiritsa ntchito njira yotsekera zitsulo kukhala zitsulo kuti mupeze kutseka kodalirika kwa zinthu zomwe zili mkati mwa vacuum ndi kupanikizika kwabwino. Pambuyo pa njira yokhazikika yochiritsira, kukhwima kwapakati pa kupukuta pamwamba pa cholumikizira cha ultra-high choyera chomwe chikukhudzana ndi sing'anga kumatha kufika 10% μ In. (0.25 μ m) Ra; Pambuyo pa njira yochiritsira ya ultra-high choyera, kukhwima kwapakati pa pamwamba popukutidwa pokhudzana ndi sing'anga kumatha kufika 5 μ In. (0.13 μ m) Ra. Nati ya cholumikizira cha ultra-high choyera imapangidwa ndi dzenje lozindikira kutayikira, lomwe limathandizira kuzindikira kutayikira. Ulusi wa nati umakonzedwa ndi njira yasiliva yopangira kuti ulusi usamawonongeke ndikuchepetsa chiopsezo cha kulumikizidwa kwa ulusi panthawi yoyika.

Zovala zazing'ono zolumikizidwa ndi matako

Kupanikizika kwa kapangidwe kake kumawerengedwa kutengera ASME B31.3 ndi ASME B31.1. Kapangidwe kake ndi kakang'ono komanso kakang'ono, kokhala ndi miyeso yolondola. Mapeto a welding ndi owongoka opanda ma burrs, ndipo makulidwe a khoma ndi ofanana. Akhoza kugwirizana kwambiri ndi mapaipi a EP ndikuwonjezera kukhazikika kwa welding. Kukhwima kwa pamwamba pa cholumikizira kumatha kufika 5 μ In. (0.13 μ m) Ra, kukhwima kwapakati pa pamwamba pambuyo pa chithandizo chanthawi zonse ndi 10 μ In. (0.25 μ m) Ra. Malumikiza okonzedwa mwapadera ndi oyeretsedwa ndi oyenera machitidwe aukhondo kwambiri, njira za photovoltaic, ndi zina zotero, okhala ndi mitundu yosiyanasiyana ya kukula komwe mungasankhe.

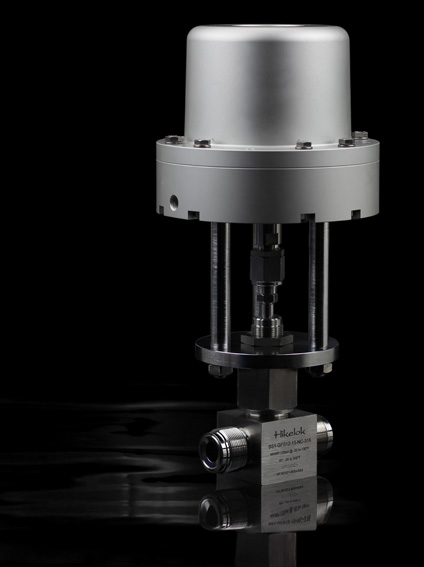

2,Ma valve otsekedwa okhala ndi chiyero chapamwamba kwambiri

Kuthamanga kwa ntchito kumatha kufika pa 1000 psig (68.9 bar) ndipo kukana kutentha kwakukulu ndi 482 ℃ (900 ℉). Tikhoza kupereka chitsulo chosapanga dzimbiri cha 316L, 316L VAR ndi zinthu zosiyanasiyana zosakaniza. Kapangidwe ka tsinde la valavu kangathandize kuonetsetsa kuti tsinde la valavu likuyenda bwino. Kapangidwe ka mutu wa valavu wosazungulira kamachepetsa kuwonongeka kwa malo okhala valavu, ndipo chitoliro chopangidwa bwino chomwe chimapangidwa bwino chimapereka magwiridwe antchito odalirika komanso moyo wautumiki. Kugunda kwa chitoliro chopangidwa ndi valavu kumayendetsedwa mosamala, zomwe zimapangitsa kuti chitetezo ndi moyo wautumiki wa chitoliro chopangidwa ndi valavu ziyende bwino.

Kuthamanga kwa ntchito kumatha kufika pa 500 psig (34.4 bar) ndipo kukana kutentha kwakukulu ndi 93 ℃ (200 ℉). Zipangizo zosapanga dzimbiri za 316L ndi 316L VAR, mitu ya ma valve a PCTFE yokhazikika imagwirizana ndi media zambiri, ndipo mitu ya ma valve a PI (polyimide) ikhoza kuperekedwa. Kapangidwe kotetezeka komanso kodalirika ka chipewa cha ma valve, chitoliro chopangidwa molondola chimapereka magwiridwe antchito odalirika komanso moyo wautumiki, zomwe zimapangitsa kutseka kwa valavu ya ma valve a ma valve kukhala kotetezeka komanso kodalirika. Tsinde la valavu yoyendetsera yopangidwa mwapadera ndi losalala.

Kuthamanga kwa ntchito kumatha kufika pa 375 psig (25.8 bar) ndipo kukana kutentha kwakukulu ndi 82 ℃ (180 ℉). Chitsulo chosapanga dzimbiri cha 316L chokhala ndi kapangidwe kake ka madzi ambiri. Kapangidwe ka tsinde la valavu kamatsimikizira kuyenda kodalirika kwa tsinde la valavu, ndipo kapangidwe ka mutu wa valavu wosazungulira kamachepetsa kuwonongeka kwa malo okhala ndi valavu. Kapangidwe ka thupi la valavu yooneka ngati Y kamatsimikizira kuti malo olowera ndi otulukira a valavu ali pamzere womwewo, zomwe zimapangitsa kuti madzi aziyenda bwino komanso kuchepetsa kukana kwa madzi. Chithandizo cha kupukuta kwa electrochemical pamwamba pamkati, choyera komanso chosalala. Chokhala ndi kuthamanga kwakukulu kwa madzi, magwiridwe antchito ambiri otseka, komanso chitetezo chambiri, ndiye chisankho chabwino kwambiri cha machitidwe ogawa mpweya woyeretsa kwambiri, machitidwe oyeretsa, machitidwe osefera, ndi machitidwe ogawa mankhwala oyeretsa kwambiri.

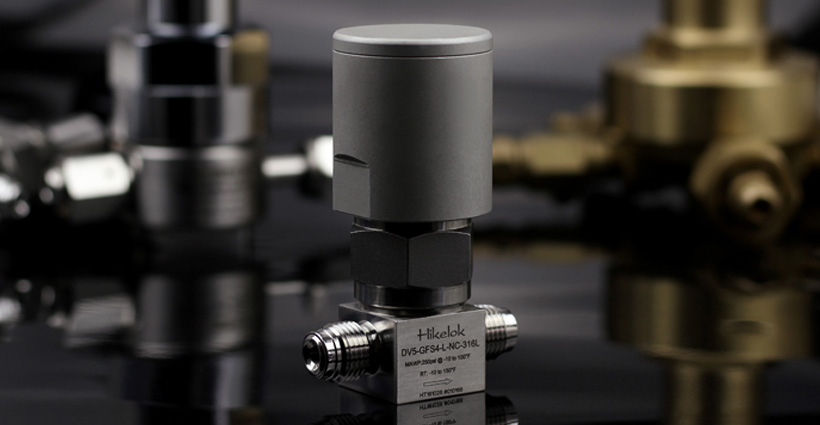

3、 Ma valve ochepetsa kuthamanga kwa magazi oyeretsedwa kwambiri

Ichi ndi chipangizo chowongolera kupanikizika, chomwe chimagwiritsidwa ntchito makamaka kuwongolera kupanikizika kwa kumtunda ndi kumunsi kwa madzi ndi makina, kusintha zokha pa intaneti, ndikuwunika kupanikizika kwa makina oyankha nthawi yeniyeni. Kupanikizika kwakukulu kwa chinthucho kumatha kufika 3500psig (241bar), ndipo kuthamanga kwa mpweya kumasankhidwa malinga ndi momwe zinthu zilili pantchito. Zipangizo zingapo zotsekera mipando ya ma valve zimasankhidwa, zomwe zingagwiritsidwe ntchito mu mpweya wowononga komanso mikhalidwe yapadera ya mpweya, zoyenera mikhalidwe ndi malo osiyanasiyana ogwirira ntchito. Pamwamba pa chinthucho pamapukutidwa ndi electrochemically mpaka mainchesi 10 (0.25) μ m) Ra, diaphragm ndi thupi la valavu zimatsekedwa ndi chitsulo chokwanira komanso chodalirika kwambiri.

Mitundu iwiri ya kupanikizika (3045psig/210bar) ndi kupanikizika kochepa (250psig/17.2bar) ikupezeka kuti musankhe. Zipangizo za thupi la valavu ya 316L VAR ndi 316L VIM-VAR zilipo, ndi zosankha zingapo zogwirira ntchito pamanja komanso pneumatic. Kapangidwe ka valavu ya PCTFE yotsekedwa bwino imagwiritsa ntchito zida za Elgiloy diaphragm kuti iwonjezere mphamvu ndi kukana dzimbiri, yokhala ndi moyo wautali komanso kupukuta kwamkati kwamagetsi mpaka 5uin (0.13) μ m) Ra, kuchuluka kwa kutayikira kwa helium ndi kochepera 1 × 10-9std cm3/s

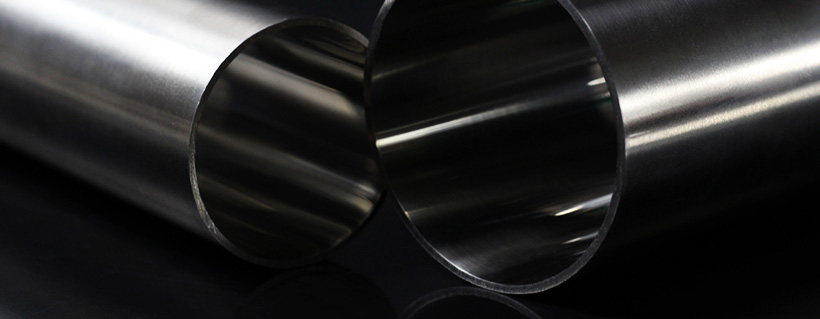

Machubu a EP

Kupukuta kwamagetsi kwamkati ndi electrochemical yokhala ndi kukhwima kwa 10 μ In. (0.25 μ m) Ra, pamwamba pakunja pakhala pakupukuta kwamakina, kutsukidwa ndi asidi ndi njira zina, zomwe zimapangitsa kuti pakhale chitetezo chowala kwambiri. Kuchulukitsa nthawi 4 kuposa chitetezo kuti zitsimikizire kuti ntchitoyo ndi yotetezeka komanso yodalirika.

Zomwe zili pamwambapa ndi zomwe zimagwiritsidwa ntchito kwambiri mumakampani opanga ma semiconductor. Hikelok ikutsatira zomwe zikuchitika mumakampani opanga ma semiconductor ndipo imagwiritsa ntchito luso lake lopanga zinthu zambiri kuti ibweretse zinthu zabwino kwambiri komanso zapamwamba kwambiri kumakampaniwa! Kuti mudziwe zambiri zokhudza kuyitanitsa, chonde onani buku lothandizira kusankha tsamba lovomerezeka la Hikelok. Ngati muli ndi mafunso aliwonse okhudza kusankha, chonde funsani akatswiri ogulitsa pa intaneti a Hikelok omwe amagwira ntchito maola 24.

Kuti mudziwe zambiri zokhudza kuyitanitsa, chonde onani zomwe mwasankhamakatalogupaWebusaiti yovomerezeka ya HikelokNgati muli ndi mafunso aliwonse okhudza kusankha, chonde funsani akatswiri ogulitsa pa intaneti a Hikelok omwe amagwira ntchito maola 24 pa intaneti.

Nthawi yotumizira: Meyi-09-2024