Nhanganyaya: Mumakore achangopfuura, nekukwira nekukurumidza kwemotokari itsva dzesimba uye huchenjeri hwekugadzira, kudiwa kwema semiconductors kwakaramba kuchikura. Kufambira mberi nekukurumidza kwetekinoroji yehungwaru kwakakurumidzisa kuchinja kwehukuru hwe semiconductor kubva padanho re microelectronic kuenda padanho re atomiki. Ma semiconductors echizvarwa chechitatu anounza nguva itsva yekuvandudzwa kwemhando yepamusoro! Panguva imwe chete, maitiro ekugadzira akaomawo. Ndezvipi zvigadzirwa zvinobva kuHikelok zvinogona kubatsira mukuvandudzwa kwema semiconductor? Ngatidzidzei zvakawanda pamwe chete!

Matekinoroji ari kusimukira akadai sehungwaru hwekugadzira uye data hombe ndiwo masimba makuru ekusimudzira, zvichikonzera kudiwa kwekubatanidza mashandiro makuru kuita machipisi madiki. Izvi zvinoreva kuti maitiro ekugadzira achava akaoma, achida kugona kupindura nekukurumidza uye kuvimbika kwakanyanya kwezvikamu kuti ive nechokwadi chekuti kutakurwa kwemakemikari kwakanyatsojeka kuchava chinhu chinonyanya kukosheswa.

Nekuda kwekunyatsorongeka uye kuoma kwekugadzira machipisi e semiconductor, ingave mavharuvhu ekudzora gasi chaiwo kana mapipeline connectors ekutakura magasi emagetsi, vanofanirwa kutevedzera zvinodiwa zveASTM neSEMI industry uye vane hunhu hunotevera:

1. Zvinhu zvesimbi isina ngura zvinofanirwa kunatswa uchishandisa VAR kana VIM-VAR yakachena kwazvo kuti zvive nechokwadi chekuti kuchena kwakanyanya kunobva kwairi;

2. Nzvimbo yemukati inobatwa nechinhu ichi inofanira kuitwa zvinhu zvakaita sekukwesha kwemagetsi uye kupfava kuti chigadzirwa chisanyanya kuchena ukuwo ichivandudza kuramba kwengura;

3. Zvigadzirwa zvesimbi isina ngura nepurasitiki zvinofanirwa kusangana nezvinodiwa neASTM neSEMI indasitiri zvakaita sekudzora hunyoro hwemukati, kudzora ongororo yekabhoni (TOC), uye kudzora kusvibiswa kwemaion.

Zvigadzirwa zveHikelok zvine hutsananguro hwepamusoro-sorosangana nezvinodiwa neindasitiri yesemiconductor yezvinhu zvine mvura uye tevedzera mitemo yeASTM neSEMI industry, kusanganisira kusarudzwa kwezvinhu zvisina kugadzirwa, tekinoroji yepamusoro yekugadzirisa, uye kuyedzwa kwekuunganidza munzvimbo yekuchengetera isina guruva ine mazinga zana. Mhando dzezvigadzirwa dzinosanganisira mavharuvhu ekuderedza kumanikidzwa kwakanyanya, mavharuvhu ediaphragm akachena zvakanyanya, mavharuvhu ebellows akasimbiswa zvakanyanya, mapaneru akabatanidzwa, mafittings ekuchenesa kwakanyanya, uye machubhu eEP. Mhando dzakasiyana-siyana dzehukuru dziripo, uye kugadzirisa kunogona kuitwa zvichienderana nezvinodiwa zvekuisa panzvimbo yacho.

1,Zvishongedzo zvekuchenesa zvakanyanya & Zvishandiso zvakasungirirwa pamagaro

Zvishongedzo zvekuchenesa zvakanyanya

Kushandisa fomu yekuvhara simbi kuita simbi kuti zvikwanise kuvharwa zvakanaka kwezvigadzirwa zviri mukati me vacuum uye positive pressure range. Mushure memaitiro ekurapa akajairwa, avhareji yekukwesha kwepamusoro pejoin yekuchena kwakanyanya panosangana nechinhu ichi inogona kusvika 10% μ In. (0.25 μ m) Ra; Mushure memaitiro ekurapa ekuchena kwakanyanya, avhareji yekukwesha kwepamusoro pejoin yekukwesha panosangana nechinhu ichi inogona kusvika 5 μ In. (0.13 μ m) Ra. Nati yekuchena kwakanyanya yakagadzirwa neburi rekuona kubuda kwemvura, izvo zvinoita kuti zvikwanise kuona kubuda kwemvura. Shinda dzenati dzinobatwa ne sirivha plating process kuderedza kupera kweshinda uye kuderedza njodzi yekubatanidzwa kweshinda panguva yekuisa.

Zvishandiso zveMinimary gatt zvakasungirirwa

Kumanikidzwa kwedhizaini kunoverengerwa zvichibva paASME B31.3 neASME B31.1. Chimiro chacho chakamanikana uye chakamanikana, chine saizi chaiyo. Mugumo wekunamira wakatwasuka usina maburi, uye ukobvu hwemadziro hwakafanana. Inogona kuenderana zvakanyanya nemapombi eEP uye inovandudza kugadzikana kwekunamira. Kushata kwemukati mejoini kunogona kusvika 5 μ In. (0.13 μ m) Ra, avhareji yekushata kwepamusoro mushure mekurapwa kwakajairika i10 μ In. (0.25 μ m) Ra. Majoini akacheneswa uye akagadzirwa akakodzera masisitimu ekuchena kwakanyanya, maitiro e photovoltaic, nezvimwewo, ane mhando dzakasiyana dzehukuru dzekusarudza kubva.

Kumanikidzwa kwekushanda kunogona kusvika 1000 psig (68.9 bar) uye kudzivirira kwakanyanya kupisa i482 ℃ (900 ℉). Tinogona kupa 316L, 316L VAR simbi isina tsvina nezvimwe zvinhu zvakasiyana-siyana zve alloy. Dhizaini yekubatanidza stem yevharuvhu inogona kuve nechokwadi chekufamba kwakavimbika kwestem yevharuvhu. Dhizaini yemusoro wevharuvhu isingatenderere inoderedza kupera munzvimbo yechigaro chevharuvhu, uye pombi yakaumbwa nemazvo inopa kushanda kwakavimbika kwekuvhara uye hupenyu hwebasa. Kurova kwepombi yakaumbwa nemarara kunodzorwa zvakasimba, zvichivandudza kuchengetedzeka uye hupenyu hwebasa hwepombi yakaumbwa nemarara.

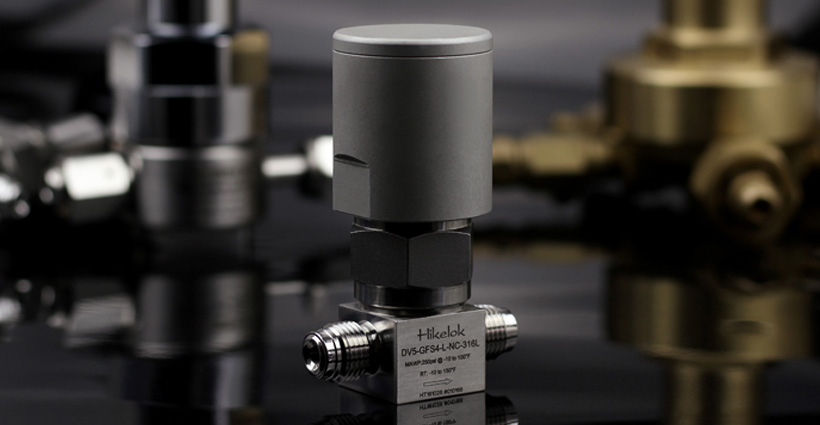

Kumanikidzwa kwekushanda kunogona kusvika 500 psig (34.4 bar) uye kudzivirira kwakanyanya kupisa i93 ℃ (200 ℉). Zvinhu zvesimbi zvisina tsvina zve316L ne316L VAR, misoro yemavharuvhu ePCTFE anoenderana nemidziyo yakawanda, uye misoro yemavharuvhu ePI (polyimide) inogona kupihwa. Dhizaini yechivharo chevharuvhu chakachengeteka uye chakavimbika, pombi yakaumbwa nemazvo inopa kushanda kwakavimbika kwechivharo uye hupenyu hwebasa, zvichiita kuti chivharo chevharuvhu yepombi yakakombama chive chakachengeteka uye chakavimbika. Huru yevharuvhu yakagadzirwa zvakanaka yakatsetseka.

Kumanikidzwa kwekushanda kunogona kusvika 375 psig (25.8 bar) uye kuramba kupisa kwakanyanya i82 ℃ (180 ℉). 316L simbi isina tsvina ine dhizaini yepamusoro yekuyerera. Dhizaini yekubatanidza tsinde yevharuvhu inoita kuti tsinde yevharuvhu ifambe zvakanaka, uye dhizaini yemusoro wevharuvhu isingatenderere inoderedza kupera munzvimbo yechigaro chevharuvhu. Dhizaini yemuviri wevharuvhu yakaita seY inoita kuti nzvimbo inopinzwa neinobuda yevharuvhu zvive panzvimbo imwe chete, zvichipa kumhanya kwakanyanya kwekuyerera uye kuderedza kuramba kwekuyerera. Kurapa kwe electrochemical polishing pamusoro wemukati, kwakachena uye kwakapfava. Iine kumhanya kwakanyanya kwekuyerera, kushanda kwakanyanya kwekuvhara, uye kuchengetedzeka kwakanyanya, ndiyo sarudzo yakanakisa yemasisitimu ekugovera gasi ane hutsanana hwakawanda, masisitimu ekuchenesa, masisitimu ekusefa, uye masisitimu ekugovera makemikari ane hutsanana hwakawanda.

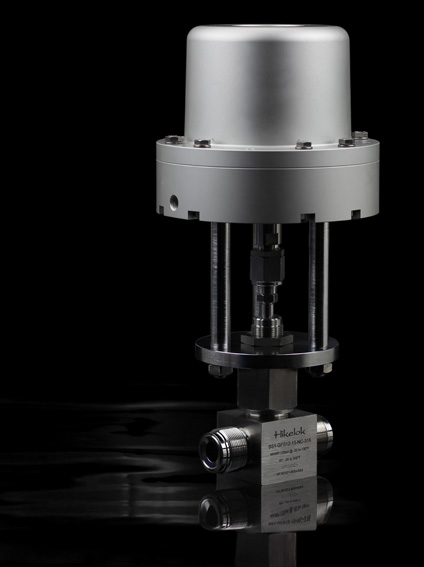

Ichi chishandiso chinodzora kumanikidzwa, chinoshandiswa zvakanyanya kudzora kumanikidzwa kwekumusoro nekudzika kwemvura uye sisitimu, chinogadzirisa otomatiki online, uye kutarisa kukosha kwekumanikidzwa kwesystem yemhinduro munguva chaiyo. Kumanikidzwa kwakanyanya kwekupinda kwechigadzirwa kunogona kusvika 3500psig (241bar), uye huwandu hwekumanikidzwa kwekubuda hunosarudzwa zvichienderana nemamiriro chaiwo ebasa. Zvinhu zvakawanda zvekuvhara zvigaro zvevharuvhu zvinosarudzwa, izvo zvinogona kushandiswa mumagasi anoparadza uye mamiriro egasi akakosha, akakodzera mamiriro akasiyana-siyana ekushanda nenzvimbo. Pamusoro pechigadzirwa chinopukutwa nemagetsi kusvika 10 inches (0.25) μ m) Ra, diaphragm nemuviri wevharuvhu zvakavharwa nesimbi zvizere nekuvimbika kwakanyanya.

Mhando mbiri dzedhiziri (3045psig/210bar) uye dhiziri shoma (250psig/17.2bar) dziripo kuti dzisarudzwe. 316L VAR uye 316L VIM-VAR valvu body materials zviripo, nesarudzo dzakawanda dzekushandisa nemaoko uye nepneumatic. Dhizaini yechigaro chevharuvhu chePCTFE chakavharwa zvizere inoshandisa Elgiloy diaphragm material kuvandudza simba uye kuramba ngura, ine hupenyu hurefu hwebasa uye electrochemical polishing yemukati inosvika 5uin (0.13) μ m) Ra, chiyero chekubuda kwehelium chiri pasi pe1 × 10-9std cm3/s

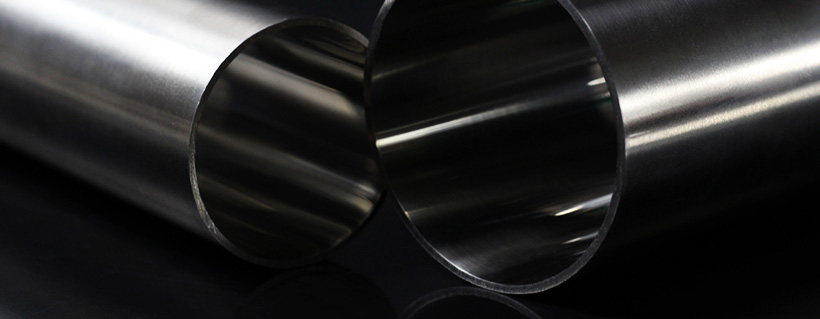

Tubhu reEP

Kuporishwa kwemagetsi kwemukati mepamusoro ne roughness ye 10 μ In. (0.25 μ m) Ra, pamusoro pekunze pakaporishwa ne mechanical, kugezwa ne acid nedzimwe nzira, zvichiratidza mamiriro akajeka ekuchengetedza. Yakapetwa ka4 pane chinhu chekuchengetedza kuti ive nechokwadi chekushandiswa kwakachengeteka uye kwakavimbika.

Zviri pamusoro apa ndizvo zvinoshandiswa zvakanyanya muindasitiri yesemiconductor. Hikelok inoenderana nekufambira mberi kweindasitiri yesemiconductor uye inoshandisa ruzivo rwayo rwakakura rwekushandisa zvigadzirwa kuti iunze zvigadzirwa zvinoshanda uye zvemhando yepamusoro kuindasitiri! Kuti uwane rumwe ruzivo rwekuodha, ndapota tarisa bhuku rekusarudza rewebhusaiti yepamutemo yeHikelok. Kana uine mibvunzo yekusarudza, ndapota taura nevashandi vekutengesa veHikelok vanoshanda maawa makumi maviri nemana online.

Kuti uwane rumwe ruzivo rwekuodha, ndapota tarisa sarudzo yachomakatarogupaWebhusaiti yepamutemo yaHikelokKana muine mibvunzo yekusarudza, ndapota taurai nevashandi vekutengesa veHikelok vanoshanda maawa makumi maviri nemana online.

Nguva yekutumira: Chivabvu-09-2024