Intshayelelo: Kwiminyaka yakutshanje, ngokunyuka ngokukhawuleza kwezithuthi ezintsha zamandla kunye nobukrelekrele bokwenziwa, imfuno yee-semiconductors iqhubekile nokukhula. Uphuhliso olukhawulezileyo lwetekhnoloji ekrelekrele lukhawulezise utshintsho lobukhulu be-semiconductor ukusuka kwinqanaba le-microelectronic ukuya kwinqanaba le-atomic. Ii-semiconductors zesizukulwana sesithathu zizisa ixesha elitsha lophuhliso olusemgangathweni ophezulu! Kwangaxeshanye, inkqubo yokuvelisa nayo iyinkimbinkimbi ngakumbi. Zeziphi iimveliso ezivela kwiHikelok ezinokunceda ngophuhliso lwee-semiconductor? Masifunde ngakumbi kunye!

Iitekhnoloji ezintsha ezifana nobukrelekrele bokwenziwa kunye nedatha enkulu zizinto eziphambili eziqhuba uphuhliso, nto leyo ekhokelela kwisidingo sokupakisha ukusebenza okukhulu kwiitships ezincinci. Oku kuthetha ukuba inkqubo yokuvelisa iya kuba nzima ngakumbi, ifune amandla okuphendula ngokukhawuleza kunye nokuthembeka okuphezulu kwamacandelo ukuqinisekisa ukuba ukuthuthwa kweekhemikhali ngokuchanekileyo kuya kuba yinto ephambili.

Ngenxa yokuchaneka nobunzima bokwenziwa kweetshiphusi ze-semiconductor, nokuba ziivalvu zolawulo oluchanekileyo lwegesi okanye izihlanganisi zepayipi zokuthwala iigesi ze-elektroniki, kufuneka zithobele imigangatho efanelekileyo ye-ASTM kunye ne-SEMI shishini kwaye zibe neempawu ezilandelayo:

1. Izinto ezisetyenzisiweyo zentsimbi engagqwaliyo mazicocwe kusetyenziswa i-VAR okanye i-VIM-VAR ecocekileyo kakhulu ukuqinisekisa imfuneko yobunyulu obuphezulu kakhulu obuvela kumthombo;

2. Umphezulu ongaphakathi odibana nesixhobo kufuneka ungene kwiinkqubo ezifana nokupholisha nge-electrochemical kunye nokuthambisa ukuze kufumaneke ucoceko olukhulu ngelixa kuphuculwa ukumelana nokugqwala kwemveliso;

3. Iimveliso zentsimbi engagqwaliyo kunye neplastiki kufuneka zihlangabezane nemigangatho efanelekileyo ye-ASTM kunye ne-SEMI efana nolawulo lohlalutyo lomswakama wangaphakathi, ulawulo lohlalutyo lwekhabhoni ye-organic epheleleyo (TOC), kunye nolawulo lokwakheka kongcoliseko lwee-ion.

Iimveliso zochungechunge lweHikelok olucocekileyo kakhuluukuhlangabezana neemfuno zoshishino lwe-semiconductor kwiinxalenye zolwelo kwaye zithobele imigangatho ye-ASTM kunye ne-SEMI shishini, kubandakanya ukukhethwa kwezinto eziluhlaza, iteknoloji yokucubungula esemgangathweni ophezulu, kunye novavanyo lokuhlanganisa kwindawo yokusebenzela engenalo uthuli oluphezulu. Iintlobo zemveliso ziquka iivalvu zokunciphisa uxinzelelo oluphezulu kakhulu, iivalvu ze-diaphragm ezicocekileyo kakhulu, iivalvu ezitywiniweyo ze-bellows ezicocekileyo kakhulu, iiphaneli ezidibeneyo, izixhobo zokucoca eziphezulu kakhulu, kunye neetyhubhu ze-EP. Kukho iintlobo ezininzi zobukhulu ezikhoyo, kwaye ukwenziwa ngokwezifiso kungenziwa ngokweemfuno zokufakelwa kwindawo.

1,Izixhobo zokucoceka okuphezulu kakhulu & Izixhobo ezifakwe kwi-butt

Izixhobo zokucoceka okuphezulu kakhulu

Ukwamkela uhlobo lokutywina lwesinyithi kwisinyithi ukuze kufezekiswe ukutywinwa okuthembekileyo kweemveliso ngaphakathi koluhlu lwe-vacuum kunye noxinzelelo oluhle. Emva kwenkqubo yonyango eqhelekileyo, uburhabaxa obuphakathi bokupolisha umphezulu wejoyinti yobunyulu obuphezulu kakhulu xa idibene ne-medium bunokufikelela kwi-10% μ In. (0.25 μ m) Ra; Emva kwenkqubo yonyango lobunyulu obuphezulu kakhulu, uburhabaxa obuphakathi bomphezulu obupholisiweyo xa idibene ne-medium bunokufikelela kwi-5 μ In. (0.13 μ m) Ra. I-nut yejoyinti yobunyulu obuphezulu kakhulu yenzelwe umngxuma wokufumanisa ukuvuza, okwenza kube lula ukufumanisa ukuvuza. Imisonto ye-nut iphathwa ngenkqubo yesilivere yokubeka iplanga ukunciphisa ukuguguleka kwemisonto kunye nokunciphisa umngcipheko wokubandakanyeka kwemisonto ngexesha lokufakwa.

Izithako ezidityanisiweyo zeempundu ezincinci

Uxinzelelo loyilo lubalwa ngokusekelwe kwi-ASME B31.3 kunye ne-ASME B31.1. Ulwakhiwo luncinci kwaye luncinci, lunobukhulu obuchanekileyo. Isiphelo se-welding sithe tye ngaphandle kwe-burrs, kwaye ubukhulu bodonga buyafana. Lunokufikelela kwimvumelwano ephezulu neepayipi ze-EP kwaye luphucule uzinzo lwe-welding. Uburhabaxa bomphezulu wangaphakathi wejoyinti bunokufikelela kwi-5 μ In. (0.13 μ m) Ra, uburhabaxa bomphezulu oqhelekileyo emva konyango oluqhelekileyo yi-10 μ In. (0.25 μ m) Ra. Amalungu aphathwe ngokukodwa kwaye acociweyo afanelekile kwiinkqubo zobunyulu obuphezulu kakhulu, iinkqubo ze-photovoltaic, njl.njl., kunye neentlobo ezahlukeneyo zobukhulu onokukhetha kuzo.

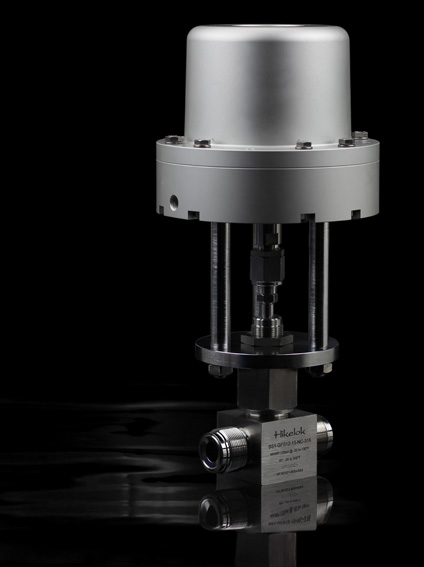

2,Ubumsulwa obuphezulu kakhulu bukhupha iivalvu ezitywiniweyo

Uxinzelelo olusebenzayo lunokufikelela kwi-1000 psig (68.9 bar) kwaye ukumelana nobushushu obuphezulu yi-482 ℃ (900 ℉). Singabonelela ngentsimbi engagqwaliyo ye-316L, 316L VAR kunye nezinto ezahlukeneyo ze-alloy. Uyilo loqhagamshelo lwesiqu sevalvu lunokuqinisekisa intshukumo ethembekileyo yesiqu sevalvu. Uyilo lwentloko yevalvu engajikeleziyo lunciphisa ukuguguleka kwindawo yesihlalo sevalvu, kwaye umbhobho wecorrugated owenziwe ngokuchanekileyo ubonelela ngokusebenza okuthembekileyo kokutywina kunye nobomi benkonzo. Ukubetheka kombhobho wecorrugated kulawulwa ngokungqongqo, okuphucula ngokufanelekileyo ukhuseleko kunye nobomi benkonzo yombhobho wecorrugated.

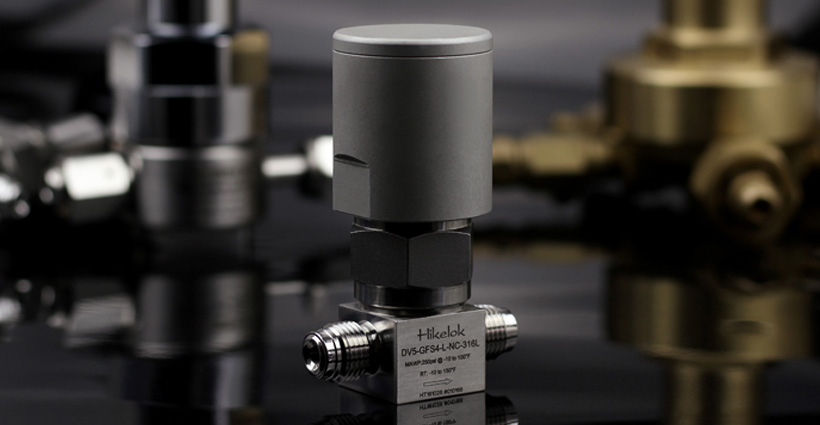

Uxinzelelo olusebenzayo lunokufikelela kwi-500 psig (34.4 bar) kwaye ukumelana nobushushu obuphezulu yi-93 ℃ (200 ℉). Izixhobo zentsimbi engagqwaliyo ze-316L kunye ne-316L VAR, iintloko zeevalvu ze-PCTFE ezizenzekelayo ziyahambelana nemidiya emininzi, kwaye iintloko zeevalvu ze-PI (polyimide) zinokubonelelwa. Uyilo olukhuselekileyo noluthembekileyo lwevalvu edibeneyo, umbhobho ogobileyo owenziwe ngokuchanekileyo ubonelela ngokusebenza okuthembekileyo kokutywina kunye nobomi benkonzo, okwenza ukutywinwa kwevalvu yombhobho ogobileyo kukhuseleke kwaye kuthembeke. Isiqu sevalvu yokuqhuba esiyilelwe ngokukodwa sigudile.

Uxinzelelo olusebenzayo lunokufikelela kwi-375 psig (25.8 bar) kwaye ukumelana nobushushu obuphezulu yi-82 ℃ (180 ℉). Izinto zentsimbi engagqwaliyo ezingama-316L ezinoyilo oluphezulu lokuhamba. Uyilo loqhagamshelo lwesiqu sevalvu luqinisekisa intshukumo ethembekileyo yesiqu sevalvu, kwaye uyilo lwentloko yevalvu engajikeleziyo lunciphisa ukuguguleka kwindawo yesihlalo sevalvu. Uyilo lomzimba wevalvu oluyimilo ka-Y luqinisekisa ukuba ukungena kunye nokuphuma kwevalvu kukwi-axis enye, kubonelela ngesantya esiphezulu sokuhamba kunye nokunciphisa ukumelana nokuhamba. Unyango lokupolisha nge-electrochemical kumphezulu wangaphakathi, lucocekile kwaye lugudile. Lunesantya esiphezulu sokuhamba, ukusebenza okuphezulu kokutywina, kunye nokhuseleko oluphezulu, lolona khetho lulungileyo kwiinkqubo zokusasazwa kwegesi zenkqubo yokucoca, iinkqubo zokucoca, iinkqubo zokucoca, kunye neenkqubo zokusasazwa kweekhemikhali zokucoca eziphezulu.

Esi sisixhobo esilawula uxinzelelo, esisetyenziselwa kakhulu ukulawula uxinzelelo oluvela phezulu nasezantsi kunye nenkqubo, sizilungisa ngokuzenzekelayo kwi-intanethi, kwaye sijonge ixabiso loxinzelelo lwenkqubo yempendulo ngexesha langempela. Uxinzelelo oluphezulu lokungenisa imveliso lunokufikelela kwi-3500psig (241bar), kwaye uluhlu loxinzelelo lokuphuma lukhethwa ngokwemeko yokwenyani yomsebenzi. Kukhethwa izixhobo ezininzi zokutywina izihlalo zeevalvu, ezinokusetyenziswa kwiigesi ezirhabaxa kunye neemeko zegesi ezikhethekileyo, ezifanelekileyo kwiimeko ezahlukeneyo zokusebenza kunye neendawo. Umphezulu wangaphakathi wemveliso upholishwe nge-electrochemically ukuya kwi-10 intshi (0.25) μ m) Ra, i-diaphragm kunye nomzimba wevalvu zitywinwe ngokupheleleyo ngesinyithi ngokuthembeka okuphezulu.

Uxinzelelo oluphezulu (3045psig/210bar) kunye noxinzelelo oluphantsi (250psig/17.2bar) ziyafumaneka ukuze zikhethwe. Izixhobo zomzimba wevalvu ye-316L VAR kunye ne-316L VIM-VAR ziyafumaneka, kunye neendlela ezininzi zokusebenza ngesandla kunye ne-pneumatic. Uyilo lwesihlalo sevalvu ye-PCTFE evalekileyo ngokupheleleyo lusebenzisa izinto ze-Elgiloy diaphragm ukuphucula amandla kunye nokumelana nokugqwala, kunye nobomi benkonzo ende kunye nokupholisha kwangaphakathi kwe-electrochemical surface ukuya kuthi ga kwi-5uin (0.13) μ m) Ra, izinga lokuvuza kwe-helium lingaphantsi kwe-1 × 10-9i-std cm3/s

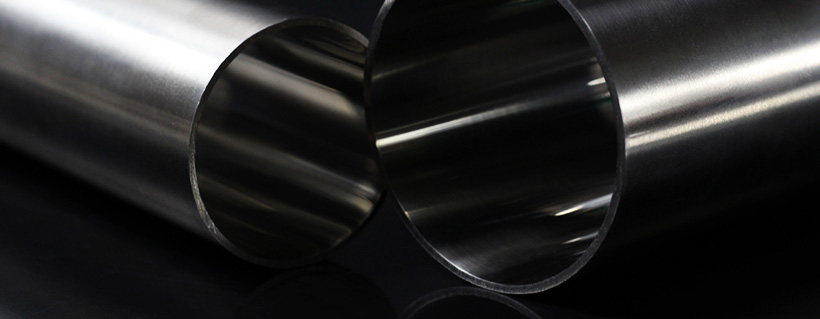

Iityhubhu ze-EP

Ukupholisha nge-electrochemical kumphezulu wangaphakathi okunoburhabaxa be-10 μ In. (0.25 μ m) Ra, umphezulu wangaphandle uye wapholisha ngoomatshini, wahlanjwa nge-asidi kunye nezinye iinkqubo, nto leyo ebonisa imeko eqaqambileyo iyonke. Iphindwe kane ngaphezu kwento yokhuseleko ukuqinisekisa ukusetyenziswa okukhuselekileyo nokuthembekileyo.

Ezi zingentla zezona zicelo zikhethwayo kushishino lwe-semiconductor. I-Hikelok ihambelana nomkhwa wophuhliso loshishino lwe-semiconductor kwaye isebenzisa amava ayo atyebileyo osetyenziso lwemveliso ukuzisa iimveliso ezisebenza kakuhle nezisemgangathweni ophezulu kushishino! Ukuze ufumane iinkcukacha ezithe vetshe zoku-odola, nceda ujonge incwadi yesikhokelo yokukhetha iwebhusayithi esemthethweni ye-Hikelok. Ukuba unemibuzo yokukhetha, nceda unxibelelane nabasebenzi abangochwephesha bokuthengisa kwi-intanethi be-Hikelok abasebenza iiyure ezingama-24.

Ukuze ufumane iinkcukacha ezithe vetshe malunga noku-odola, nceda ujonge ukhethoiikhathalogukuvuliweIwebhusayithi esemthethweni kaHikelokUkuba unemibuzo yokukhetha, nceda unxibelelane nabasebenzi abangochwephesha bokuthengisa kwi-intanethi baseHikelok abasebenza iiyure ezingama-24.

Ixesha lokuthumela: Meyi-09-2024