Ukuwelda yindlela yokudibanisa ethembekileyo kakhulu, esetyenziswa kakhulu kwimveliso yemizi-mveliso kwihlabathi liphela. Inkqubo echanekileyo yokuwelda inokuqinisekisa ukuba ijoyinti yokuwelda iqinile kwaye ayinakuvuza, ngoko ke inokudlala indima ebaluleke kakhulu yokudibanisa.

Kukho iindlela ezimbini eziqhelekileyo zokuwelda: ukuwelda kwe-socket kunye nokuwelda kwe-butt

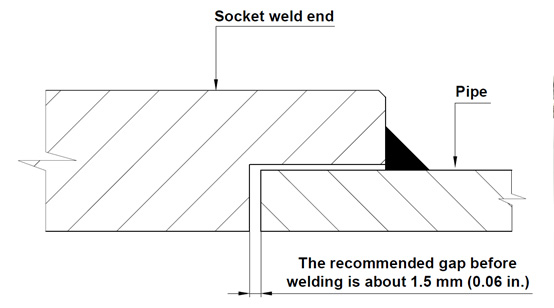

Ukuwelda isokhethi: faka umbhobho kumngxuma wesinyathelo ekupheleni kwe-socket welding uze udibanise isangqa ngaphandle ukuze ugqibezele uqhagamshelo lwe-socket welding. Ngexesha le-socket welding, faka umbhobho kumngxuma we-socket welding ude ufikelele ezantsi, uze ukhuphe umbhobho malunga ne-1.5mm (0.06in.), uze wenze i-welding, enokuthi ithintele uxinzelelo lwe-welding ngexesha le-welding.

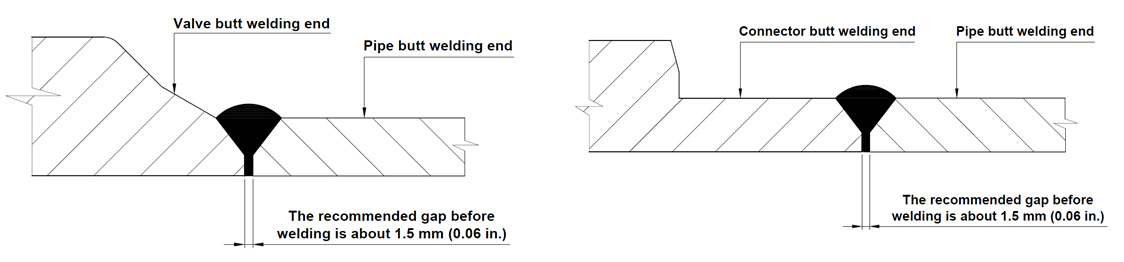

Ukuwelda ngeempundu: iindawo zokuwelda ze-weldments kuzo zombini iziphelo mazibe macala omabini, kwaye i-1.5mm (0.06in.) mayigcinwe. Emva koko hlanganisa isangqa ecaleni kwejoyinti ukuqinisekisa ukuba udonga lombhobho ludityaniswe ngokupheleleyo ukuze ufumane amandla athembekileyo. Njengoko kubonisiwe kumfanekiso, ivalvu enomdibaniso wokuwelda we-butt inokudityaniswe nge-butt ngepayipi, kwaye izixhobo ezidityanisiweyo zinokudityaniswe nge-butt ngepayipi.

Umsebenzi wokuchazwa kweenkcukacha zokuwelda

Abasebenzi bokuthungela i-Hikelok baphumelele uqeqesho lobuchwephesha kunye novavanyo, kwaye baphumeza ngokungqongqo inkqubo yokuthungela ngexesha lokuthungela ukuqinisekisa ukuba inkangeleko, umsebenzi kunye nokusebenza kweemveliso kufikelela kwimeko efanelekileyo emva kokuthungela.

Iimveliso zokuwelda zeHikelok ziqukaivalvu yenaliti, ivalvu yebhola, izixhobo ezidityanisiweyo, njl., ezinokwenziwa ngokwezifiso ngokweemeko zokusebenza zabathengi.

Ukuze ufumane iinkcukacha ezithe vetshe malunga noku-odola, nceda ujonge ukhethoiikhathalogukuvuliweIwebhusayithi esemthethweni kaHikelokUkuba unemibuzo yokukhetha, nceda unxibelelane nabasebenzi abangochwephesha bokuthengisa kwi-intanethi baseHikelok abasebenza iiyure ezingama-24.

Ixesha lokuthumela: Epreli-27-2022