Ukuze kuqinisekiswe ukusebenza kweukufakwa kwepayipi le-ferrule eliphindwe kabilimaqondana nokumelana nokugqwala, ukuvala, ukumelana nengcindezi kanye nokumelana nokudlidliza, sithathe amasampula emikhiqizweni evela kumaqoqo ahlukene ngokuhambisana ngokuqinile ne-I-ASTM F1387, i-ABSkanye nemininingwane yokuhlangana kwe-nuclear grade, futhi benze izivivinyo ezilandelayo zokuhlola. Imiphumela ikhombisa ukuthi zonke ziyaphumelela.

Ukuhlolwa kokuhlola

| Umkhiqizo | Uhlobo lokuhlola | Inqubo yokuhlola | Umphumela wokuhlolwa |

| Ukufakwa kwepayipi le-ferrule eliphindwe kabili | Ukuhlolwa kokudlidliza | Ukuhlolwa kokudlidliza kwenziwa eziqondisweni ze-X, Y kanye ne-Z zengxenye yokuhlola ngokulandelana. Imvamisa yokuhlola iphakathi kuka-4 ~ 33hz, futhi akukho ukuvuza ngesikhathi senqubo yokuhlola. | Iphasi |

| Ukuhlolwa kwengcindezi yobufakazi be-hydraulic | Indawo yokuhlola ingamanzi ahlanzekile, ingcindezi yokuhlola iphindwe ka-1.5 kunengcindezi yokusebenza, isikhathi sokubamba ingcindezi singamaminithi ama-5, futhi ukufakwa akunazo izinguquko noma ukuvuza. | Iphasi | |

| Ukuhlolwa kokumelana nokugqwala | Ukuhlolwa kwe-salt spray kokufakwa kwensimbi engagqwali kwenziwa amahora angu-168, futhi kwakungekho ndawo yokugqwala. | Iphasi | |

| Ukuhlolwa kobufakazi bomoya | Indawo yokuhlola iyi-nitrogen, ingcindezi yokuhlola iphindwe ka-1.25 kunengcindezi yokusebenza, futhi ingcindezi igcinwa imizuzu emi-5 ngaphandle kokuvuza. | Iphasi | |

| Ukuhlolwa komfutho | Umfutho wokushaya kwenhliziyo ukhuphuka kusuka ku-0 kuya ku-133% womfutho wokusebenza, bese wehlisa umfutho ungadluli ku-20 ± 5% womfutho olinganisiwe. Isamba sesikhathi sokucindezela kanye nesikhathi sokunciphisa umfutho siwumjikelezo. Ngemva komjikelezo ongaphansi kwezikhathi eziyi-1000000, akukho ukuvuza. | Iphasi | |

| Ukuhlolwa kokudiliza nokuhlanganisa kabusha | Okungenani izikhathi eziyi-10 zokungena kanye nokuhlanganiswa kabusha kokuhlolwa ngakunye ngaphandle kokuvuza. | Iphasi | |

| Ukuhlolwa komjikelezo wokushisa | Ngaphansi kwengcindezi yokusebenza, ingxenye yokuhlola kufanele igcinwe ekushiseni okuphansi - 25 ℃ amahora ama-2, kanti ingxenye yokuhlola kufanele igcinwe ekushiseni okuphezulu okungu-80 ℃ amahora ama-2. Kusukela ekushiseni okuphansi kuya ekushiseni okuphezulu kuyimjikelezo, ohlala imijikelezo emi-3. Ngemva kokuhlolwa kwe-hydraulic, akukho ukuvuza. | Iphasi | |

| Susa isivivinyo | Faka umthwalo oqinile wokudonswa ngesivinini esingaba ngu-1.3mm/min (0.05in/min). Ngalesi sivinini, finyelela inani eliphansi elivunyelwe lomthwalo wokudonswa, i-ferrule ayihlukanisiwe nokufakwa, futhi akukho ukuvuza nomonakalo esivivinyweni se-hydrostatic. | Iphasi | |

| Ukuhlolwa kokukhathala okugobile | 1. Isampula ifinyelela inani lokucindezeleka kokugoba elidingekayo yi-F1387 ngaphansi kwengcindezi yokusebenza elinganisiwe, 2. Indawo kusukela endaweni yokushintsha engu-zero kuya endaweni yokucindezela okuphezulu okuhle, kusukela endaweni yokushintsha engu-zero kuya endaweni yokucindezela okuphezulu okubi, kanye nokusuka endaweni yokucindezela okuphezulu okubi kuya endaweni engathathi hlangothi kuyimjikelezo. 3. Yenza imijikelezo engu-30000 iyonke engxenyeni yokuhlola, futhi akukho ukuvuza ngesikhathi sokuhlolwa. | Iphasi | |

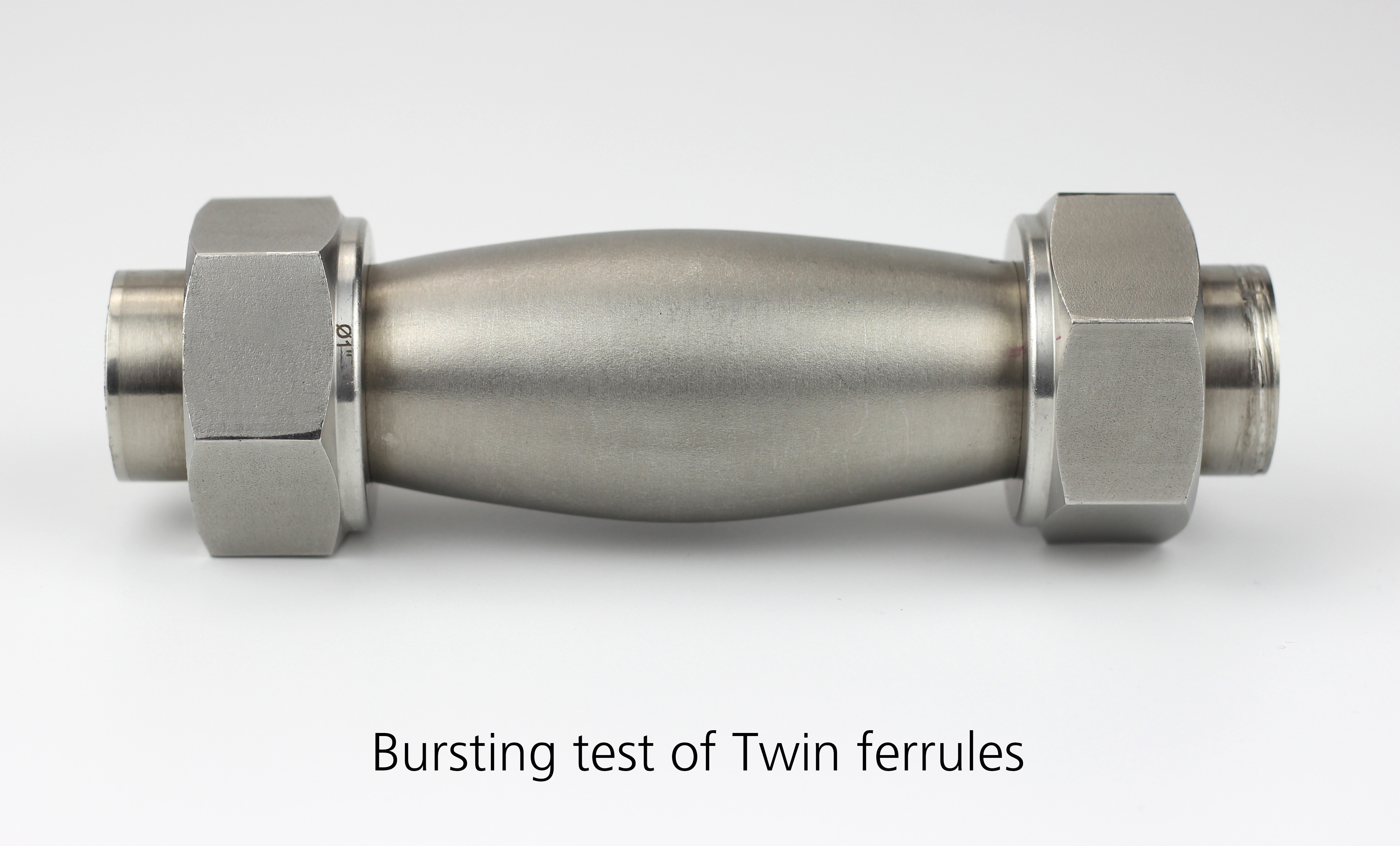

| Ukuhlolwa kwengcindezi eqhumayo | Cindezela ingxenye yokuhlola izikhathi ezingaphezu kwezine kunengcindezi yokusebenza kuze kube yilapho ithubhu liqhuma, futhi ama-ferrule akhululekile ekuweni nasekuvuzeni. | Iphasi | |

| Ukuhlolwa kokuphambuka kokujikeleza | 1. Ngenisa isikhathi sokugoba ngokusho kwe-F1387 bese usikhiya endaweni yaso. 2. Cindezela ingxenye yokuhlola ibe yingcindezi encane engaguquki engu-3.45mpa (500PSI). Gcina isikhathi sokugoba kanye nengcindezi ngesikhathi sokuhlolwa. 3. Jikelezisa ingxenye yokuhlola okungenani imijikelezo eyi-1000000 ngesivinini okungenani esingu-1750 rpm, futhi akukho ukuvuza esivivinyweni se-hydrostatic. | Iphasi | |

| Ukuhlolwa kwe-torque engaphezulu | Bopha ingxenye yokuhlola ngethuluzi elifanele bese uzungeza olunye uhlangothi kuze kube yilapho ithubhu liguquguquka unomphela noma lisuswa uma kuqhathaniswa nokufakwa futhi kungabikho ukuvuza esivivinyweni se-hydrostatic. | Iphasi

|

Ukuze uthole imininingwane eyengeziwe yoku-oda, sicela ubhekeIwebhusayithi esemthethweni yeHikelokUma unemibuzo yokukhetha, sicela uxhumane nabasebenzi bokuthengisa abangochwepheshe abasebenza amahora angama-24 online.

Isikhathi sokuthunyelwe: Feb-24-2022