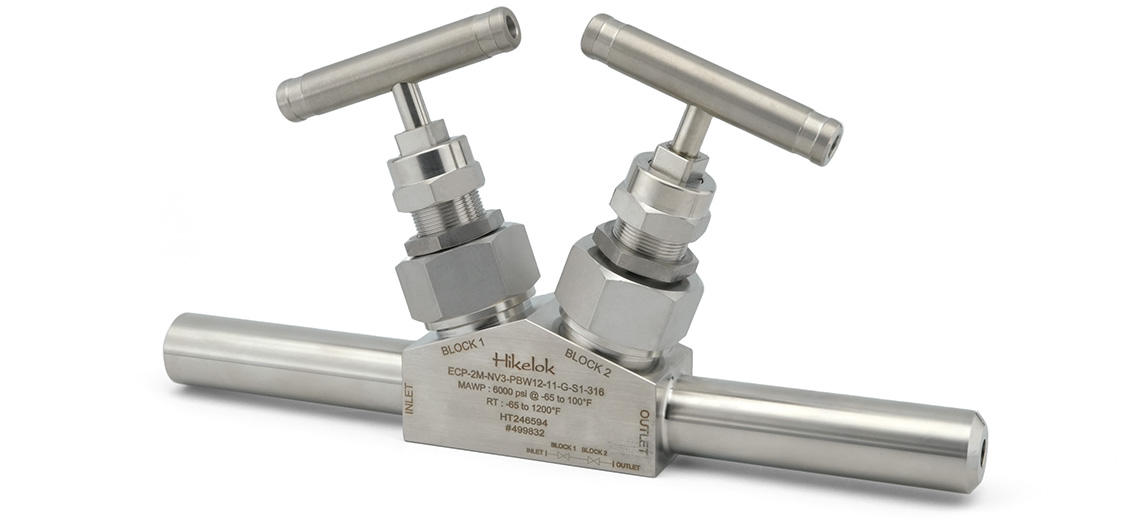

Design concept: Integrated design

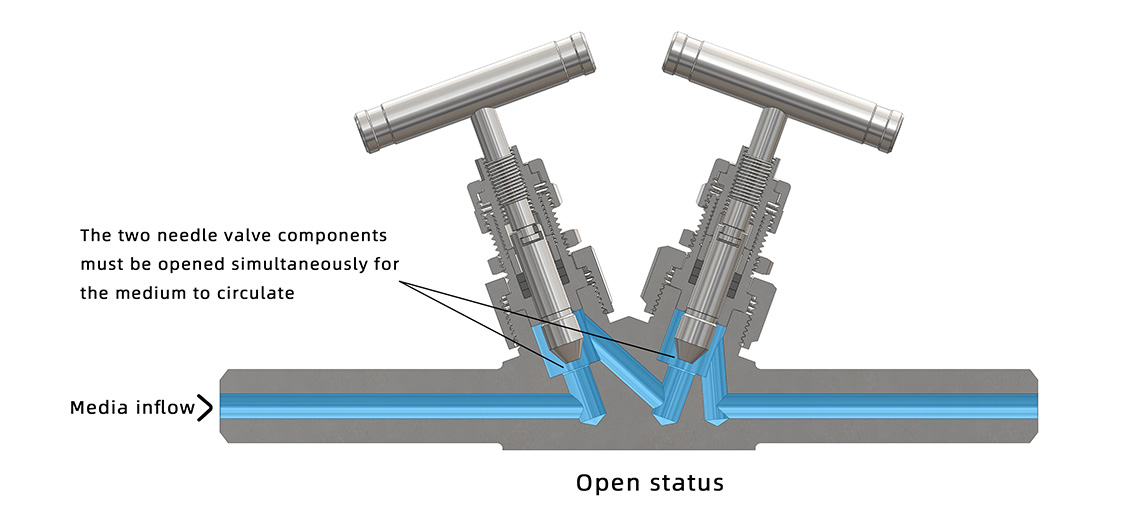

As a new product for targeted optimization of industrial pipeline connections, the integrated double isolation valve is designed with the core of "double isolation needle valve+integrated structure", and requires two needle valve parts to be opened simultaneously for the medium to flow. Compared to traditional multi valve systems, the core of this new product lies in:

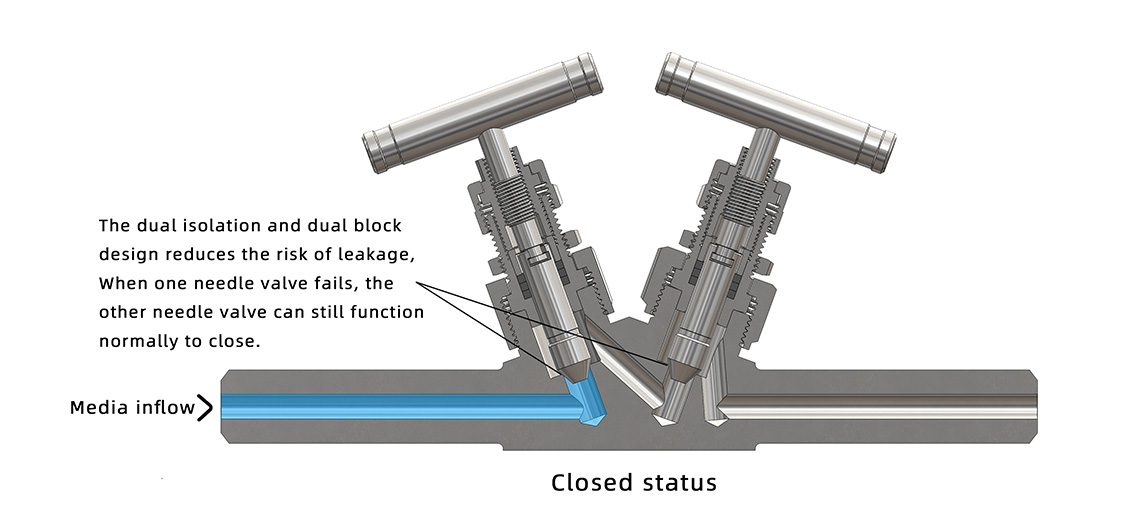

1. The dual isolation and dual block design combined with an integrated structure reduces potential leakage points and greatly improves the safety and reliability of the pipeline system;

2. Compact layout+lightweight design, reducing installation space occupation, adapting to narrow working environments, while reducing pipeline load-bearing pressure;

3. Welding port design enhances connection stability and meets long-term continuous operation requirements;

4. The needle valve assembly adopts a combined valve bonnet structure, optimizing the integration and ease of operation of the components;

Key performance: Stable adaptation to complex working conditions

Continuing the strict industrial standards in terms of performance, with parameters covering multiple scenario requirements:

1. Pressure tolerance: The highest pressure rating reaches 6000PSI, suitable for high-pressure pipeline operations;

2. Temperature range: using graphite packing, working temperature range -53 °C to 648 °C (-65 °F to 1200 °F), compatible with complex high and low temperature conditions;

3. Flow efficiency: Designed with a diameter of 9mm to ensure smooth medium flow without affecting system operation efficiency;

4. Structural strength: The one-piece forged valve body has excellent impact resistance and corrosion resistance, extending the product's service life.

Innovative details:Optimize user experience and stability

Targeted upgrades have been made in the structural design to address common industry issues, and practical value has been enhanced in the details

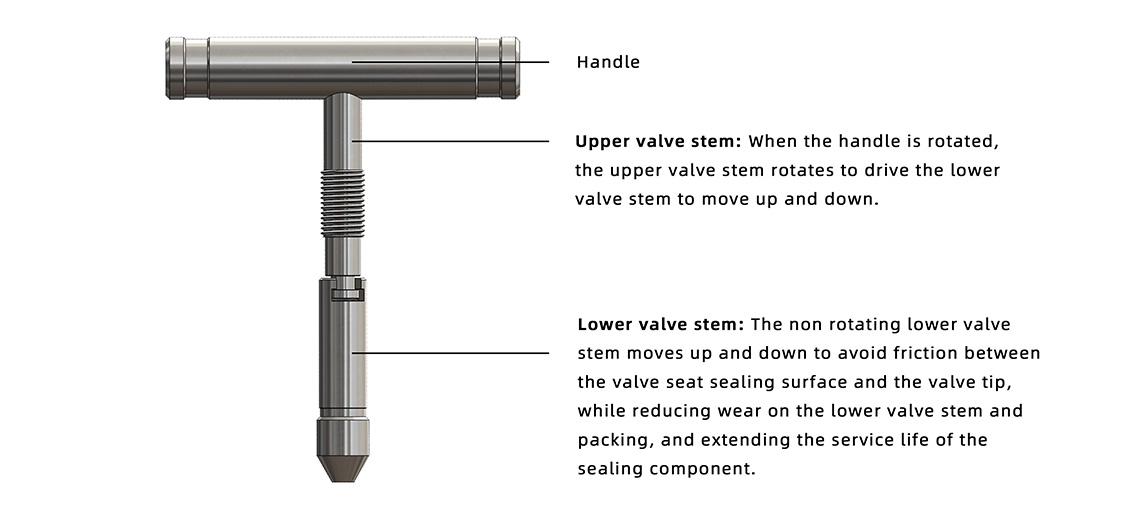

1. Innovative design of two-piece valve stem: The lower valve stem adopts non rotating up and down movement, replacing the traditional rotating lifting structure, reducing the friction loss between the valve seat sealing surface and the valve tip, while reducing the wear of the lower valve stem and packing, and extending the service life of the sealing component;

2. Back sealing protection: The valve has a back sealing function when fully open, providing dual protection of sealing performance and reducing the risk of leakage;

3. High quality threading process: The valve stem thread is rolled and formed, with better mechanical strength and wear resistance, and is not easily deformed;

4. Medium purity guarantee: The lubricating grease on the upper valve stem thread is isolated from the system medium to avoid contaminating the medium.

Scope of application: Multi industry scenario adaptation

This integrated dual isolation valve can be widely used in:

1. Petrochemical industry, natural gas extraction and transportation;

2. Electricity (thermal power, nuclear power), metallurgy, and pharmaceutical industries;

3. High pressure pipeline system and wide temperature operating environment;

4. Process and instrument connection scenarios with limited space.

For more ordering details, please refer to the selection catalogs on Hikelok's official website. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

Post time: Dec-11-2025