Double Ferrule Tube Fittings

Double Ferrule Tube Fittings - Union

Double Ferrule Tube Fittings - Bulkhead Union

Double Ferrule Tube Fittings - Union Elbow

Double Ferrule Tube Fittings - Union Tee

Double Ferrule Tube Fittings - Union Cross

Double Ferrule Tube Fittings - Male Connector

Double Ferrule Tube Fittings - Female Connector

Double Ferrule Tube Fittings - Bulkhead Male Connector

Double Ferrule Tube Fittings - Bulkhead Female Connector

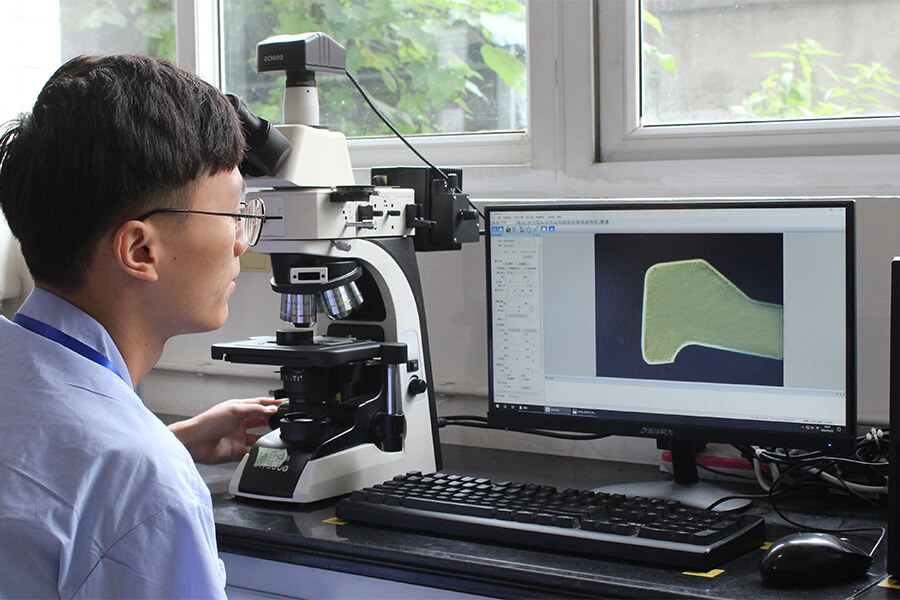

The Structure of Hikelok Double Ferrule Tube Fittings

Advanced low-temperature carburizing technology is adopted to provide reliable guarantee for ferrules in practical application.

Nut is silver plated to avoid seizure during installation.

The thread adopts rolling process to improve the hardness and finish of the surface and prolong the service life of double ferrule tube fittings.

The advantage of Hikelok double ferrule tube fittings

Pass ASTM F1387 standard type tests

The hardness process of back ferrule to ensure corrosion resistance and sealing

Silver plated nut to prevent thread biting

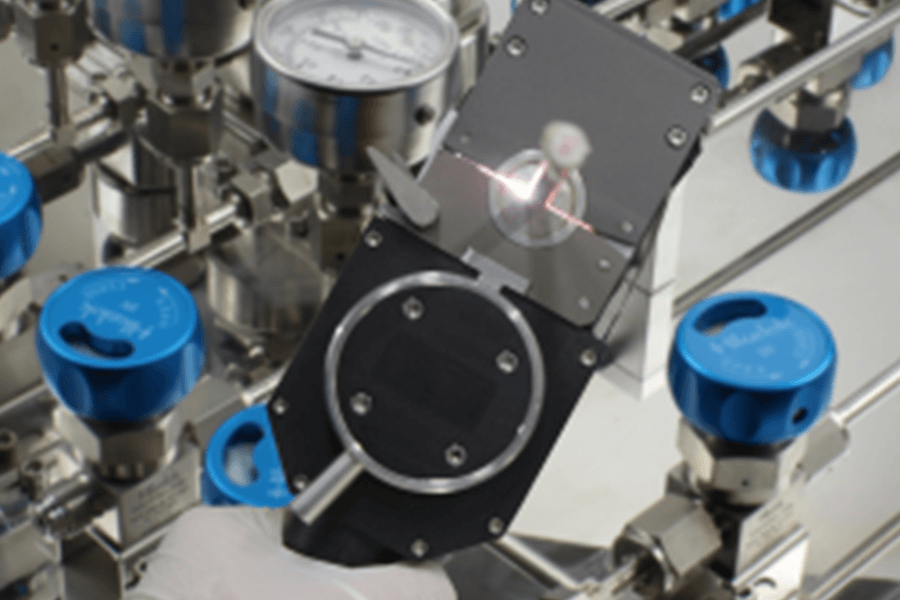

Complete Type Tests Have Proven Hikelok Double Ferrule Tube Fittings Under Harsh Working Conditions

01

Liquid sealing test

1.5 times the working pressure test

02

Reassembly test

repeat 10 times, gas working pressure test

03

Static pressure strength test

4 times working pressure test

04

Vacuum test

vacuum degree 1 × 10-4, helium leakage rate less than 1 × 10-8

05

Gas seal test

higher than 1.5 times nitrogen test

06

Liquid pulse test

frequency from 0.5 to 1.7 Hz, 106 cycles

07

Vibration test

frequency between 23 and 47 Hz, 107 cycles

08

Thermal cycle

alternating temperature between - 25 and 80 ℃, air pressure test after 5 cycles

09

Fire resistance test

fire at 800 ℃ for 30 minutes

10

Corrosion resistance test

salt spray test for 168 hours

11

Deep water test

the test is equivalent to 3048m seabed working condition (30MPa external pressure)

12

Pullout test

pressurize with design pressure, and pull out with axial load force for 5 minutes

How to make correct installation of double ferrule tube fittings?

● Use a sharp tube cutter to cut the tubing

● Use a deburring tool to remove burrs from the inner and outer ports of the tubing

● Insert the tubing into the bottom of the twin ferrule tube fitting or valve, mark the position of the nut relative to the tubing with a marker pen, and complete the installation by 1-1/4 turns. Remember not to install based on intuition or torque.

For specific installation instructions, please refer to the installation guide videos of Hikelok double ferrule tube fittings .

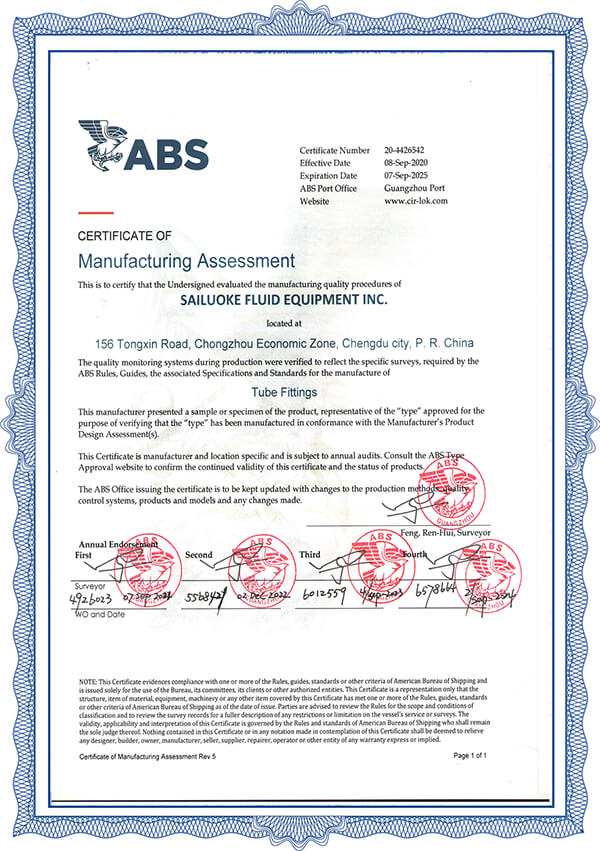

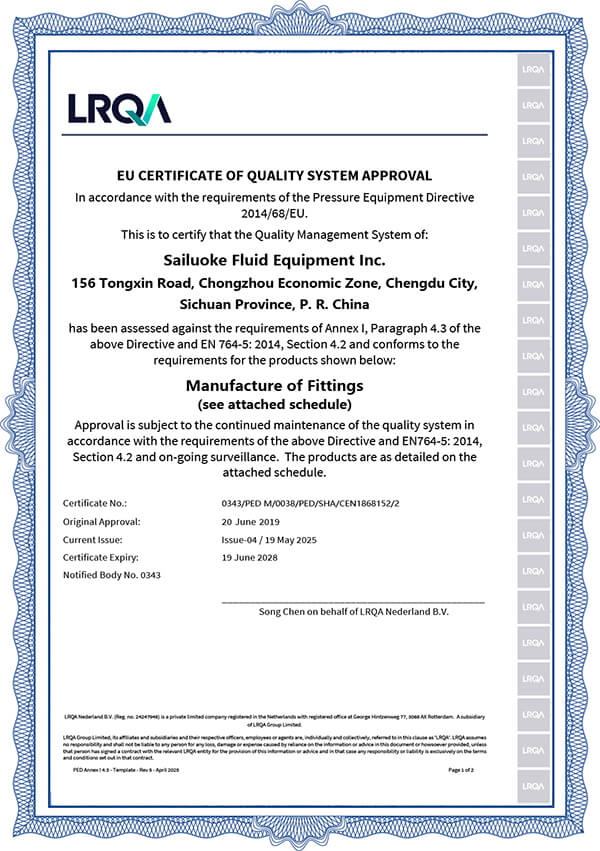

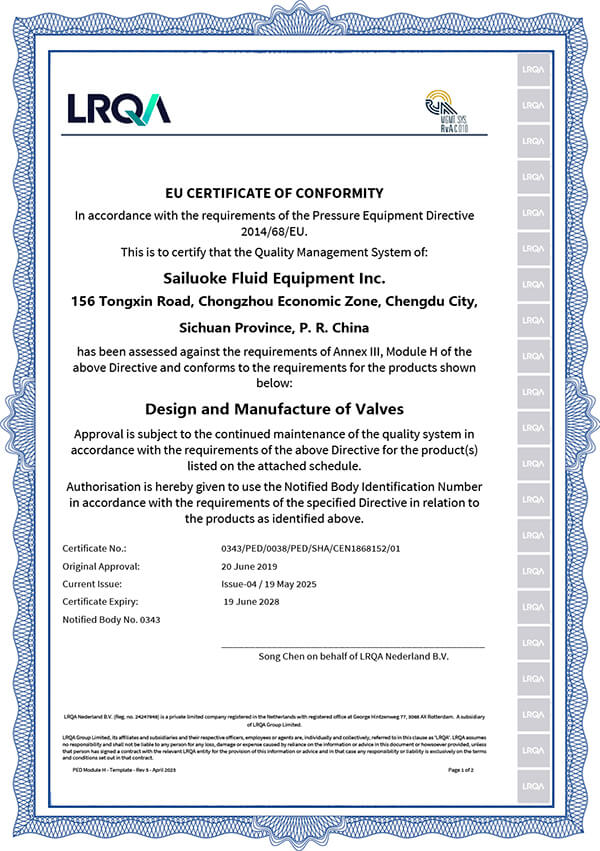

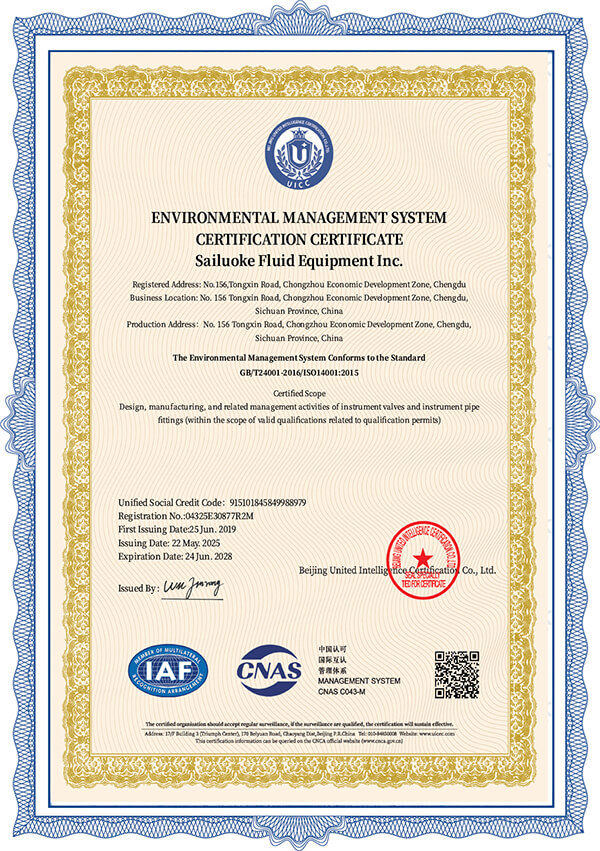

Certificate Display

ABS

PED - Fittings

PED - Valves

ISO9001

ISO14001

ISO45001

About Hikelok