The use of austenitic stainless steels is limited due to the low hardness, lower resistance and the risk of galling. Since these steels cannot be hardened by conventional heat treatment processes without reducing the corrosion resistance.

The Hikelok SuperHASS ferrule creates a strong mechanical hold on the tube.

SuperHASS improves the hardness of austenitic stainless, without affecting the corrosion resistance. Even enhance corrosion resistance after SuperHASS.

# Improvement of the wear resistance

# Prevention of galling

# Full retention of corrosion resistance

# Retention of non-magnetic properties

# Improvement of the fatigue strength

# No addition of elements which were not already present in the material

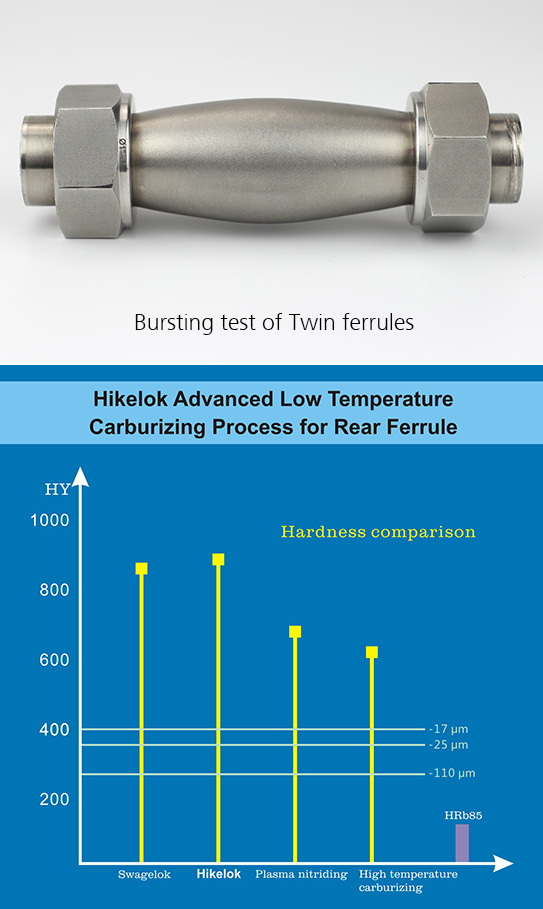

SuperHASS increases the surface hardness of austenitic stainless steel to a level 800 to 1200 HV 0.05 comparable with 66 to 74 HRc.

Characteristics of SuperHASS parts

# No change in shape or size

# No change in surface roughness

# No change in colour

SuperHASS improves

# Unique to Hikelok double ferrule fittings

# Hardness ≥ 800 HV

# Depth ≥ 25 Micron

# No reduction in base stainless steel corrosion resistance

Tube surface Hardness of ASTM A 269 hardness max. Rb 90 uses 100KG 1/16” diameter ball which crushes tube and takes average of hardness from outside diameter to core diameter. Vickers micro hardness test uses 50 gramme diamond cone which indents the tube and gives an accurate hardness measurement at any point from the outside diameter to the cone.