The construction of industrial fluid system is inseparable from the instrumentation pipe fittings as connections. In various applications such as high-pressure environment, extreme working conditions or dangerous gas-liquid transportation, the small figure of threaded fittings can be seen everywhere. Their excellent performance in pressure resistance, vibration resistance and sealing helps the fluid system operate more safely and stably, making them trusted and used by more people.

To build a safe fluid system, the premise is to select the correct thread. If you want to select the correct thread, you need to identify it first.

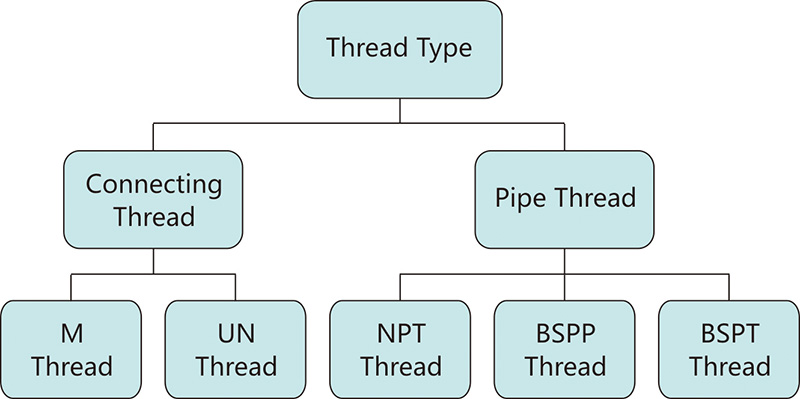

Common thread types of Hikelok

There are two types of threads commonly used by Hikelok, one is connecting thread, which is divided into M thread and UN thread, and the other is pipe thread, which is divided into NPT thread, BSPP thread and BSPT thread. This paper mainly takes pipe thread as an example.

Types of pipe threads

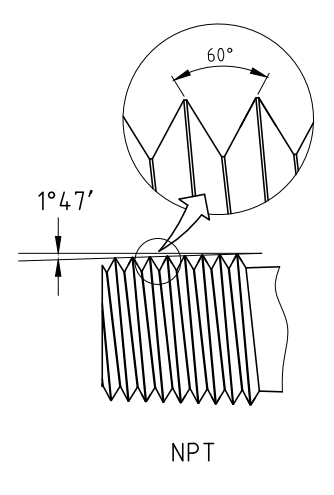

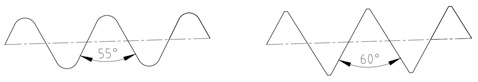

(1) NPT thread (American National Standard Pipe Thread), using ASME B1 20.1 standard, the tooth profile angle is 60 °, the tooth top and bottom are in a plane state, and the taper of conical thread is 1 ∶ 16, which is generally called taper thread.

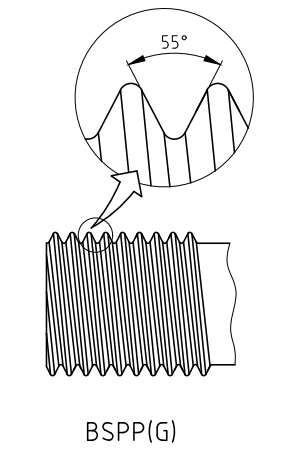

(2) BSPP thread, corresponding to G thread (British Standard Parallel Pipe), uses ISO 228-1 standard, the tooth profile angle is 55 °, the tooth top and bottom are arc-shaped, and the internal and external thread are cylindrical pipe thread, which are generally called parallel thread.

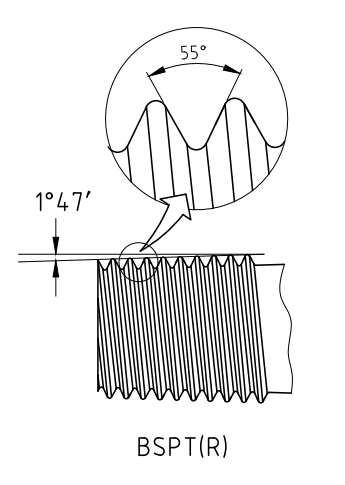

(3) BSPT thread, corresponding to R thread (British general sealing pipe thread), uses ISO 7-1 standard, the tooth profile angle is 55 °, the tooth top and bottom are circular arc, and the taper of conical thread is 1∶16. Generally known as taper thread.

How to confirm the specifications of three pipe threads

From the above information, we can know that pipe threads can also be classified into two categories: taper thread and parallel thread. Therefore, when distinguishing thread, we must first distinguish whether they are taper thread or parallel thread.

Preliminary identification

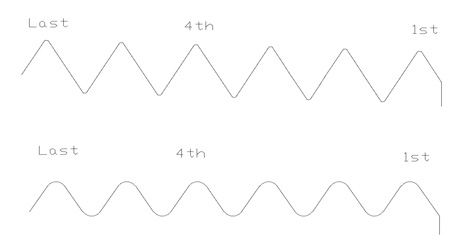

Preliminary judgment can be made according to whether the thread has taper. Use a vernier caliper to measure the diameter between the tooth tips on the first, fourth and last full thread according to the position shown in the figure below. If the diameter gradually increases or decreases, it indicates that the thread has taper, which is a BSPT thread or NPT thread in the taper thread. If all diameters are the same, it indicates that the thread has no taper and is a parallel thread BSPP thread.

Further confirmation

There is only one BSPP thread for parallel thread, so it is necessary to further distinguish whether it is BSPT thread or NPT thread in conical thread.

Tooth profile angle measurement: judged according to the tooth profile angle, the BSPT thread with a tooth profile angle of 55 ° and the NPT thread with a tooth profile angle of 60 °.

BSPT Thread NPT Thread

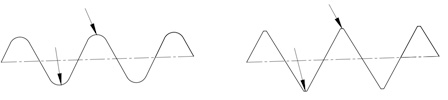

Look at the tooth shape: judge according to the shape of the tooth top and tooth bottom. The BSPT thread is on the round top and round bottom, and the NPT thread is on the flat top and flat bottom.

BSPT Thread NPT Thread

Final judgment

The following two tools are needed to accurately confirm the thread type.

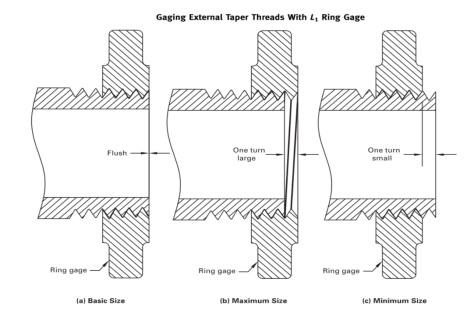

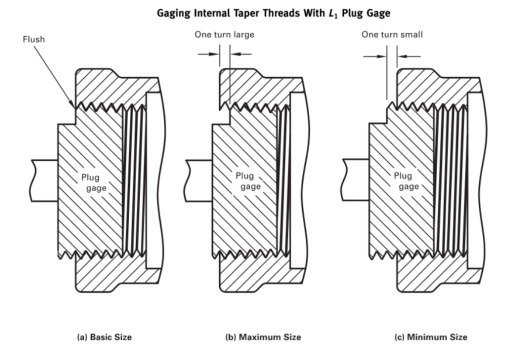

Method 1: use the thread gauge and select the corresponding thread gauge for final confirmation. The measured thread is perfectly screwed with the thread gauge. If the corresponding thread gauge inspection rules are passed, the thread specification is the actual specification of the measured thread.

Method 2: use the tooth gauge and select the corresponding tooth gauge for comparison until the tooth gauge fits perfectly with the measured thread, then the thread specification is the actual specification of the measured thread.

In addition to the above methods, we can also check the corresponding thread standards of the three threads after measuring the thread crown diameter with the vernier caliper and judging the taper thread and parallel thread, and find out the thread specification with the same thread crown diameter as the measured thread in the thread standard for further confirmation, but the final judgment still needs the help of thread gauge and tooth gauge.

When purchasing Hikelok pipe fittings, it is recommended to install and use it together with Hikelok control valves. You can choose needle valve, ball valve, proportional relief valve, metering valve, check valve, valve manifolds, sampling system, etc., so as to make the connection of fluid system more safe and efficient.

For more ordering details, please refer to the selection catalogs on Hikelok's official website. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

Post time: Mar-28-2022