Pipeline is the most important part of a perfect fluid system. Before selecting the pipeline, it is necessary to understand the pipeline connector, fluid properties and installation environment, so as to confirm the conditions that the pipeline required by the system should meet, such as surface state, material requirements, hardness standard, wall thickness, diameter and length. After collecting the above information, the correct pipeline selection can meet the system installation and ensure the reliable operation of the system without leakage.

Hikelok's pipeline products include tubing and pipe. How to choose when connecting the system? We can understand their differences in detail from the following four aspects, and then make a decision in combination with the working conditions.

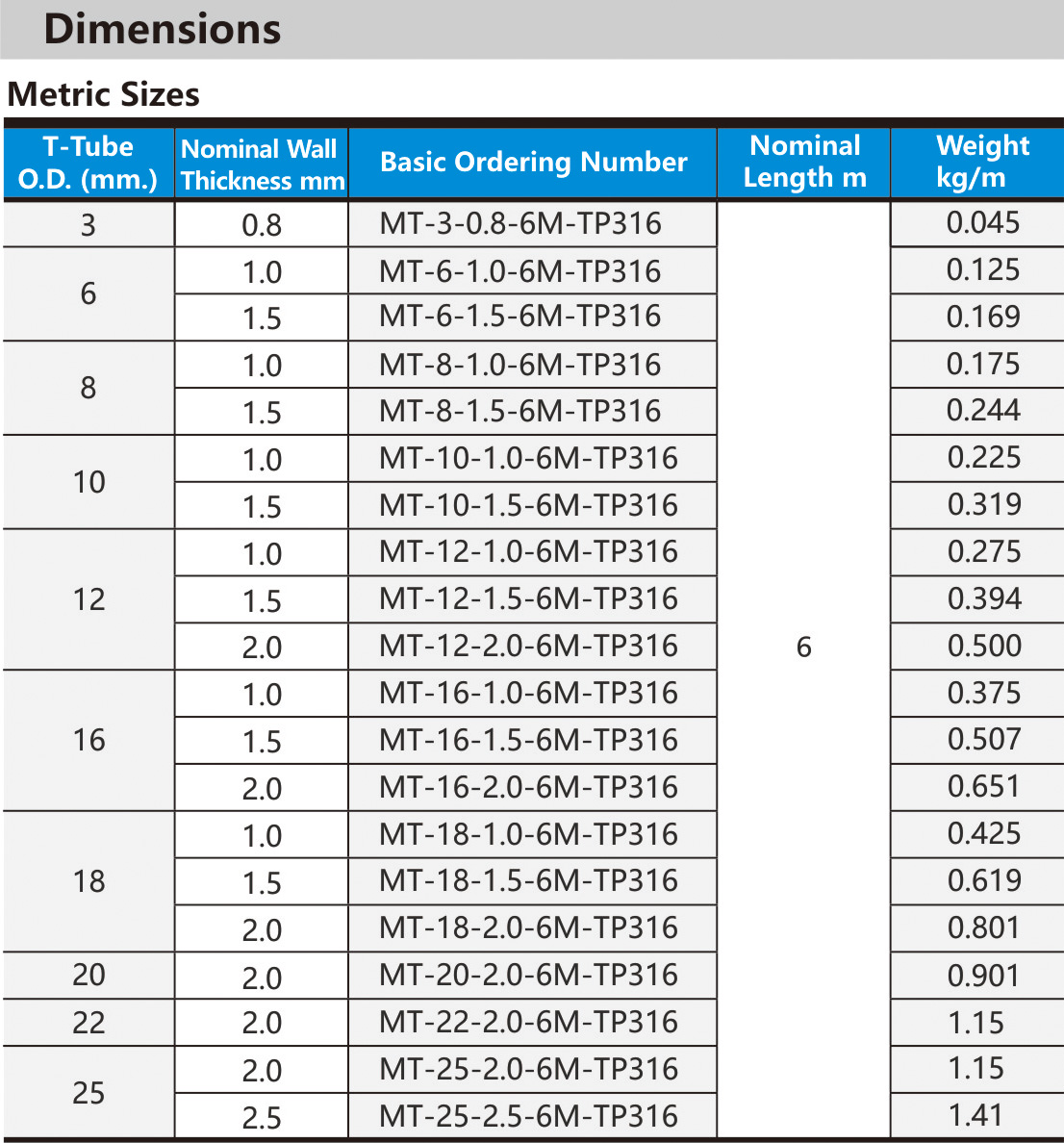

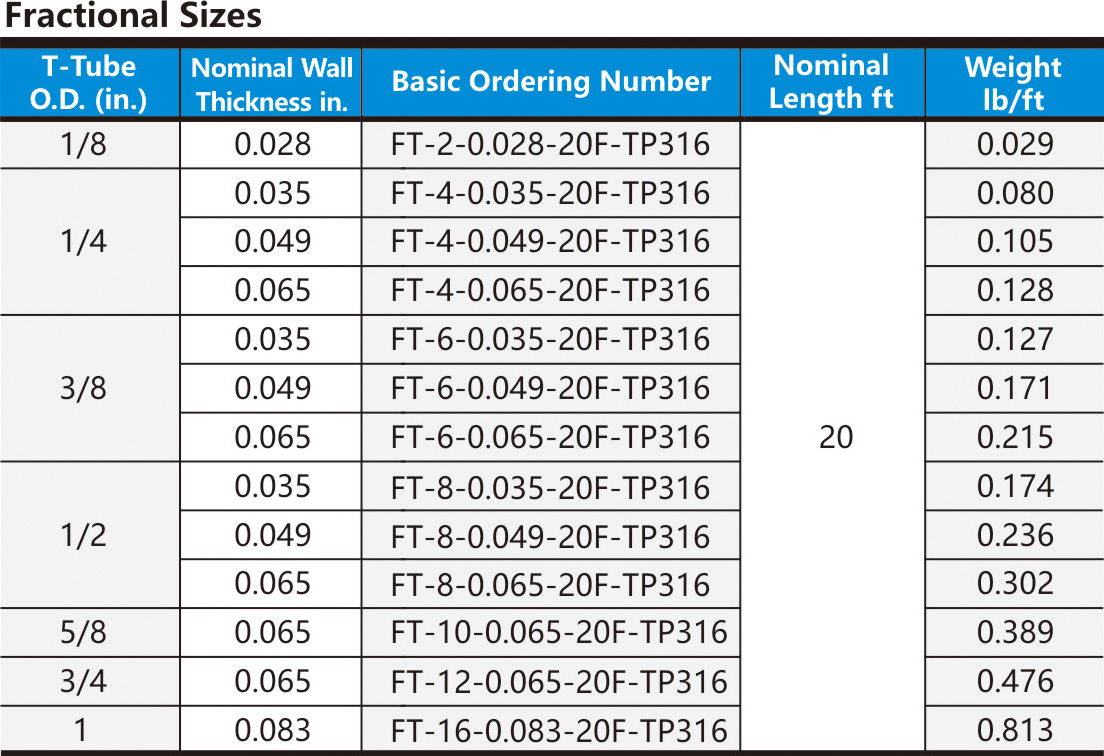

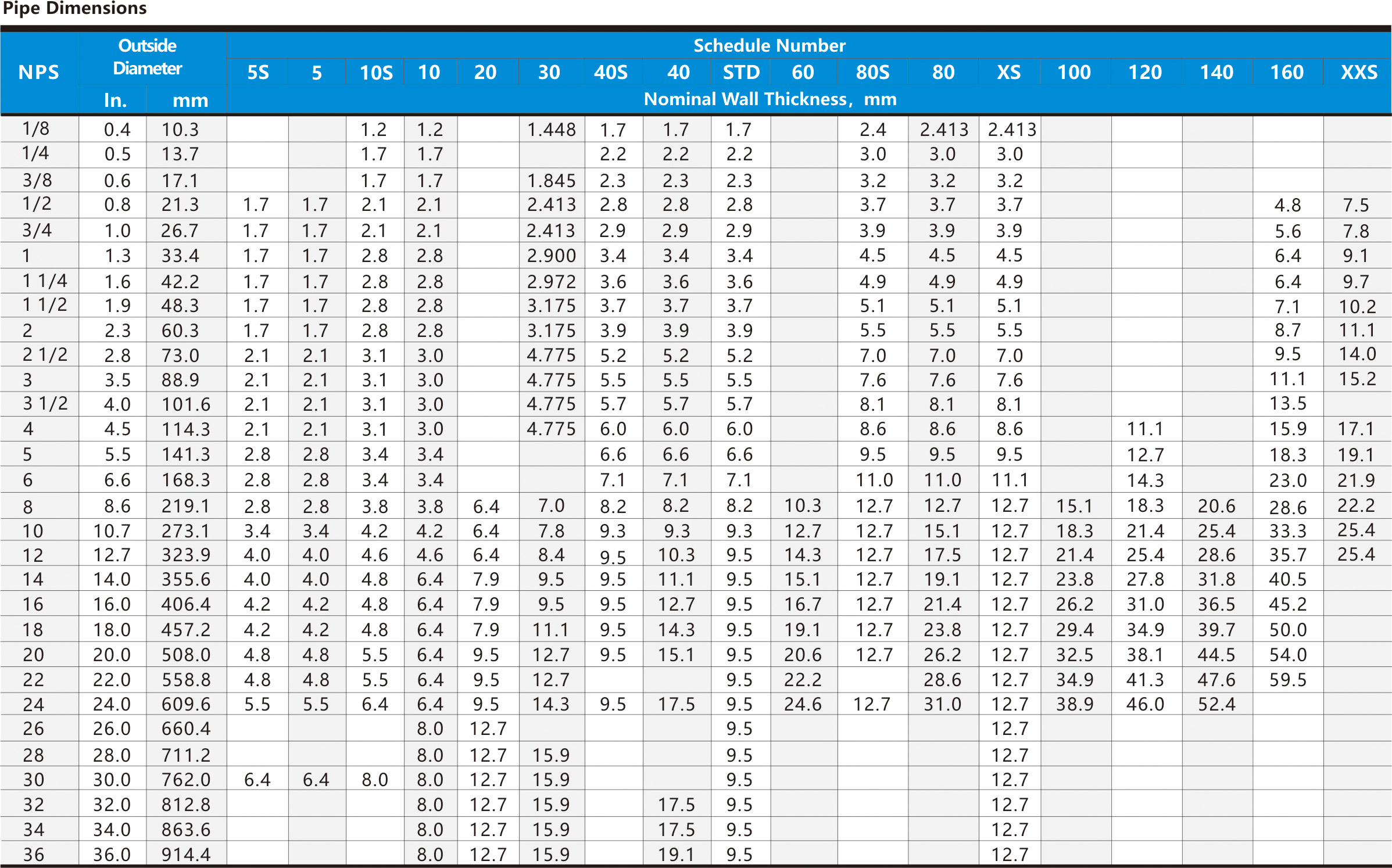

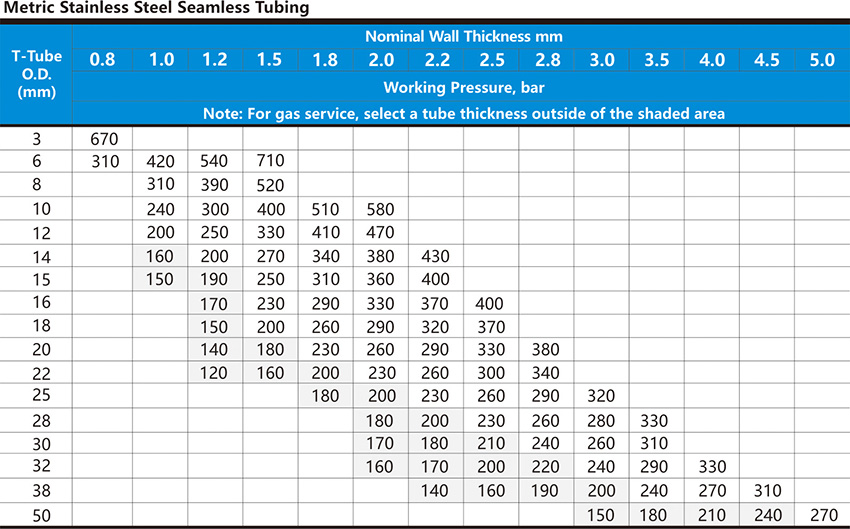

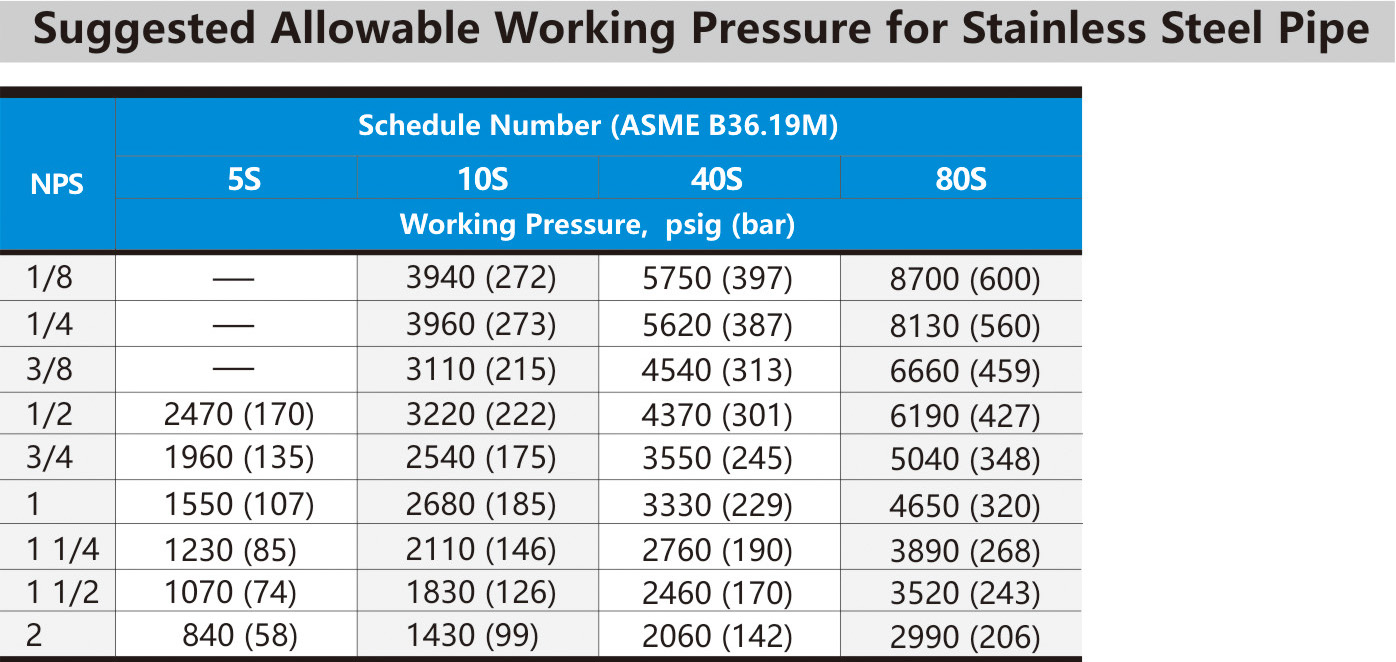

1. Different specifications and identifications. Tubing is represented by outer diameter and wall thickness, including fractional tubing and metric tubing. Pipe is represented by NPS (nominal pipe size) + schedule No. here NPS is not the actual outer diameter of pipe, but the nominal size.

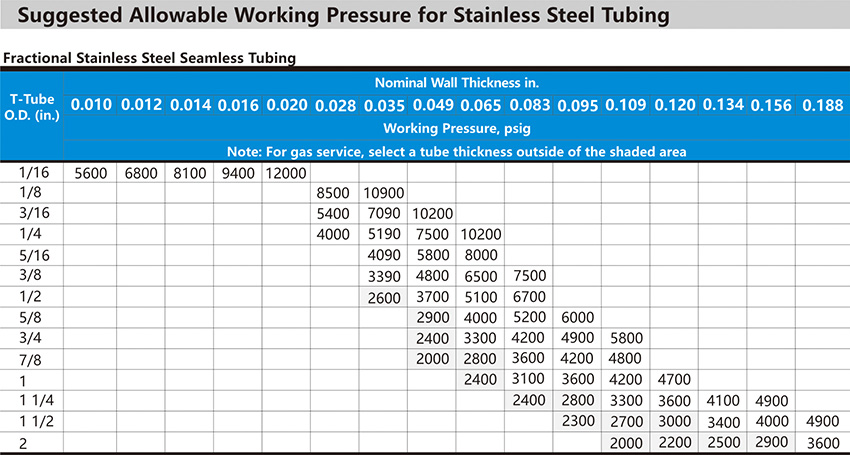

2. Different product standards. The tubing implements the ASTM A269 A213 SA213 standard, and the surface is generally required to be annealed, with the hardness not exceeding 90hrb. The pipe implements the ASTM A312 SA312 standard, and there is no requirement for the surface state. Because the standards are different, the tolerances and material States of the tubing and pipe are also different.

3. Different pressure identification. Because the tolerance should be considered in the design, and the tolerance of the relevant standards of tubing is stricter than that of pipe, so the calculated pressure bearing is also different. The tubing can accurately represent the pressure psi, while the pipe usually uses PN to represent the pressure.

4. Different applications. Due to its many specifications, easy to bend, adapt to various pipeline connections, compact structure, easy installation and maintenance, smooth flow channel and small pressure drop, tubing is often used in instrument connection system. Pipe has few specifications and high hardness, so it cannot be connected flexibly, so it is mostly used in power pipeline and process pipeline system.

In Hikelok's products, when ordering tubing, it can be used with twin ferrule tube fittings, needle valves, ball valves, safety valves, check valves and other valves. The syphon is made of tubing through certain process. In the sampling systems, tubing is also an essential connecting part.

For more ordering details, please refer to the selection catalogs on Hikelok's official website. If you have any selection questions, please contact Hikelok's 24-hour online professional sales personnel.

Post time: Mar-10-2022